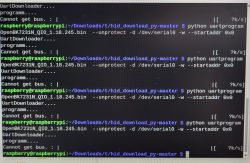

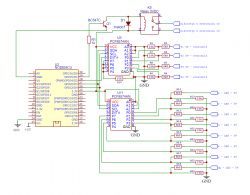

I want to use the ESP8266 (actually nodemcu v3) and the PCF8574 to read the status of a 7-segment LED in another device (three to be precise).

From the PCF8574 datasheet I read that the supply voltage should be between 2.5 to 6V which means that, at least theoretically, it should work from a 3.3V supply just like the nodemcu, however, I can also read (in the datasheet) that "VIH High-level input voltage" should be from the range of 0.7 × VCC VCC + 0.5 which means that in the case of a 3.3V supply, for the high state a minimum of 2.31V and a maximum of 3.8V is needed, while "VIL Low-level input voltage" from the range –0.5 0.3 × VCC i.e. -0.5V to 0.99V

I don't really know how to determine what the maximum voltage can be on these 7-segment LEDs their designation is KT10521BJ1B-A unfortunately I couldn't find an datasheet for exactly this model.

I am wondering how to safely connect the PCF8574 to these 7-segment LEDs, Will it be safe directly for both the device I want to read the information from and mine. Or should I use a voltage divider on each input and additionally (or only) connect a resistor in series that will limit the current flow to a maximum of a few mA i.e. 4k7 .

.

From the PCF8574 datasheet I read that the supply voltage should be between 2.5 to 6V which means that, at least theoretically, it should work from a 3.3V supply just like the nodemcu, however, I can also read (in the datasheet) that "VIH High-level input voltage" should be from the range of 0.7 × VCC VCC + 0.5 which means that in the case of a 3.3V supply, for the high state a minimum of 2.31V and a maximum of 3.8V is needed, while "VIL Low-level input voltage" from the range –0.5 0.3 × VCC i.e. -0.5V to 0.99V

I don't really know how to determine what the maximum voltage can be on these 7-segment LEDs their designation is KT10521BJ1B-A unfortunately I couldn't find an datasheet for exactly this model.

I am wondering how to safely connect the PCF8574 to these 7-segment LEDs, Will it be safe directly for both the device I want to read the information from and mine. Or should I use a voltage divider on each input and additionally (or only) connect a resistor in series that will limit the current flow to a maximum of a few mA i.e. 4k7

.

.