romulus73 wrote: Hmm, that`s why I made the first heat pump for playing COUW, in the summer 1kW was enough for the pump to heat it.

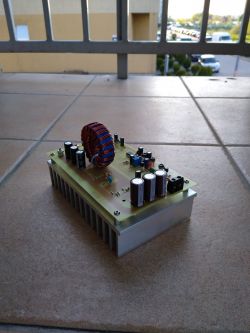

Above all, I wanted it to be cheap and reliable.

No moving parts and cheap to repair if such a situation arises.

A heat pump is like a refrigerator, you never know what will break down and when.

For example, my neighbor has been using a Viessmann ground pump since 2014 and has no complaints. Service every year and even relatively low energy consumption. Combined with recuperation, it`s great.

A friend from work installed a ground-floor heating system in 2009, spending over PLN 60,000, and has been heating his house with gas for two years because his controller broke down and, unfortunately, they have been no longer producing them since 2012.

In short, the pump needs to be replaced and I can`t afford a new one.

Maybe I don`t read books, but in recent years I have read many warranty documents for various equipment from A to Z and I am blown away.

I do not deny the decision to purchase expensive and maintenance-free heating devices and I do not intend to discourage anyone from purchasing them, after all, it is a great comfort that is appreciated these days.

However, I think that many people, like me, are looking for DIY alternatives to devices available on the market and that is why the material was posted on this forum 😉