I can write with satisfaction that the thing has moved and is playing!

.

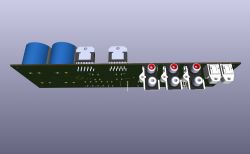

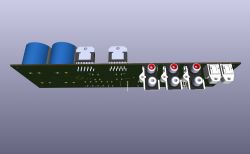

In the photo you can see how it came out. You can also see the makeshift aluminium channel heat sink, the TST160/073 transformer and the prototype interface board (more on that later).

I haven't checked everything thoroughly - I'm still missing the metallized 22k and 220 resistors that are supposed to go into the RIAA equalizer amplifier. The rest looks to be in working order.

The boards were made by PCBWay, a Far Eastern company advertised on Elektroda. I have specified a 70 µm (2 oz) copper layer in the parameters, and this is to keep the resistance in the power circuits as low as possible. To this end, the paths of the ground and both power lines are partially uncovered with a mask (you can see this on the PCB design). I thickened the ground line by soldering a copper wire fi 0.7 mm. I have not thickened the power supply lines for the time being. Whether these measures are necessary could be determined by measuring several copies made differently, which for obvious reasons I am unlikely to do.

Assembly was no more difficult than for similar circuits, except perhaps for capacitors C75..C78 and C86..C88. Probably they could have been placed slightly differently to make hand soldering easier. I also didn't give them fields with "thermal" connections, because I didn't want to reduce the effective cross-section of the tracks and this would have made assembly more difficult.

Because of the noise, I aimed for all resistors in the audio circuit to be of the metal-film type; as a result, due to lack of availability, some of them have a slightly different value than in the original schematic. These changes are included in the project documentation. I will have to wait a little longer for the 22k and 220k resistors. Similarly, I have not been able to purchase some capacitors with a sufficiently small tolerance (2%) and for the time being, five percent capacitors are used.

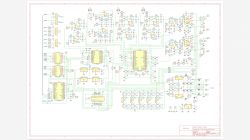

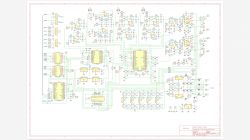

The gain adjustment range of the U15 is between -95 dB and +31.5 dB. The entire circuit is calculated so that the amplifier's full power should be achieved when the AUX inputs are driven at 0.7 V. The DAC has a nominal output signal value of 2 V and this too is supposed to be sufficient for full drive. However, often the signals have non-standard lower values and it is worthwhile that the maximum gain could be higher. I'm yet to work this out exactly, but surely the volume control should be able to be set above the 0 dB level - I'm guessing within +6..+10 dB. This will be easy to set in the software controlling the NJW1194 chip. I will determine the gain for the PHONO input (R32 and R37) when I have access to such a rare device called a turntable.

I checked the digital part using the TV's TOSLINK signal through both inputs. I didn't check the I2S1 and I2S2 inputs, well if everything works with the DIR9001, then the straight inputs shouldn't whimper either. It was necessary to put a JP2 jumper. To be honest, I still don't know how it should be configured.

Commissioning would be unfeasible without the ability to send settings (volume, tone, input selector) to U15. To achieve this, I made a simple interface to the computer, using the most readily available peripheral - a USB-RS232 adapter. This required assembling a small prototype board and "tapping" a piece of software. Schematic of the interface below, I will make the program available if anyone is interested.

.

A preliminary check of the frequency response showed that the -3dB frequency response is between about 30 Hz and 70 kHz. Such a high lower frequency is, so to speak, intentional; it came out similarly in simulation. Lowering the lower limit requires increasing the capacitance of the coupling capacitors (470 nF single and paired, especially those at the U15 inputs and C70, C71, C80, C81). In my opinion, however, this is not a problem, I do not have speakers capable of processing such low frequencies, so per balance it is a beneficial solution.

The audible noise, in my opinion, is at a low level, nor is it audible (and not visible on the oscilloscope) that there is anything disturbing happening in the area of distortion and possible excitation. There will be time for precise measurements once the whole is assembled.

Stabilisers U20 and U21 get very warm during operation, as expected (loss power of about 1.5 W), but not so much that they need to add heatsinks. The +5 V supply for the digital part, which I had planned to feed from a second power supply, is also made on this board (U23), and this is to facilitate start-up and testing. Because of the losses, it's not a very happy solution, but diode D95 will cut the load on U23 if there is external power on the CN13 connector.

My conclusions at the moment: presumably the capacitance values attached to leads 6 and 27 of the NJW1194 (gain control boost circuit) can be significantly reduced, provided the maximum value of +31.5 dB is not used. If I limit the gain to 10 dB, the 'potentiometer' part of the IC connected to ground will be of such a high value that using smaller capacitances C60-61 and C62-63 will not significantly raise the lower limit of the frequency response. I believe that limiting the gain to a maximum value of 0 dB makes it possible to dispense with these capacitances altogether. I also did a quick test by short-circuiting terminals 6 and 27 to ground, but a slight 'knock' was then heard when adjusting the gain. You can see that it is necessary to cut off the DC to make the regulation work quietly. The same is true of the capacitors connected to terminals 16 and 17, namely C68 and C69. And here smaller values would probably suffice. If I check this at some point, I will give exact conclusions.

In the final amplifier, the servo circuit (U16, C71, R74, C81, R84) behaves very well. The DC component at the loudspeaker outputs is in the single millivolts and no instability can be seen when driven. The big plus of this solution is that there is no need for a large capacitance in the LM3886 feedback. Worse - an electrolytic capacitor is often used here, which can definitely have a bad effect on distortion levels. I recommend the online article 'Selecting Capacitors to Minimise Distortion in Audio Applications', by Zak Kaye of Texas Instruments.

Now it's time to do the design of the STM32 controller with display, the power supply for the digital part. including RB-Pi.

@sq3evp

Will there be smartphone control? There will be many different things, plans are extensive. The board on display is intended to be an audio hardware base for the Raspberry Pi, with everything the heart desires included.

.

.

.

.