.

.

Welcome.

Some time ago I started my adventure with PLC programming. To start with, I found that Siemens LOGO! was sufficient. Creating a program in FBD language is quite transparent but, as you know, the created program must somehow affect reality. It is a good idea to test the written programme on a workbench in order to identify and repair potential errors before the whole assembly is assembled in the final location. This involves simulating certain states to the controller at its inputs and visualising states at its outputs to determine if the application is functioning as expected. I found that combining with switches, lights, potentiometers, etc. was not very convenient. I found signal simulators dedicated to LOGO! on the web, but for various reasons I refrained from buying one. I decided that I would design and make my own simulator. It was to be a compact design providing all the basic signals for the PLC under test. And so the device I called SIMAT-25 was created, and many factors determined this name.

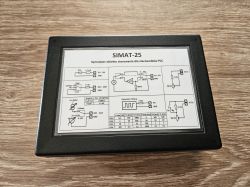

The complete device is shown in the photograph below.

.

.

The case is a Z33 model from a well-known company in the industry. Dimensions: height 46.0 mm, width 140.0 mm, length 190.0 mm. On the lid there is a plate showing in simplified form the idea of the construction of the individual signal tracks. For those in the trade, this information contains all the necessary data. The lid protects the panel components from mechanical damage. When the lid is removed, the panel is visible.

.

.

On the side of the case there is a DC 2.5/5.5 socket for connecting a 24VDC power supply ("plus" inside).

.

.

The simulator is designed for PLCs supplied with 24V DC. The power supply is connected to the ARK connectors with the description +24V DC and GND. The GND terminal is common to the power supply and the simulated signals. In this way, the power supply for the simulator can be taken from the system in which the PLC under test is running. It is also convenient to use an additional 24VDC power supply and connect it to the DC 2.5/5.5 connector on the side of the housing. In this way, the controller under test can be powered by wires plugged into the ARK +24VDC and GND connectors and in this way it is the simulator that powers the controller under test. This way of power supply suits me so far.

The main electronics board of the simulator is also the front panel. All electronic components are smd type and are located on the underside of the board. The main board itself has protection against reverse connection of the supply voltage, while the corresponding pins of the DC supply connector and the ARK +24VDC and GND terminals are directly connected to each other.

Correct connection of the power supply is indicated by the illumination of the red LED with the description PWR.

Sets of potentiometers, switches, LEDs, displays are given names identifying the supported function/signal. The corresponding names are also found on the ARK screw terminals, so it is immediately clear which connector is the signal of interest.

Signals and their characteristics:

DO1-DO8: three-state digital output: logic 1 "High" state (short-circuits to plus supply), logic 0 "Low" state (short-circuits to GND) and high impedance state (output "hangs in the air"). There is a 1k/1W resistor in series at the output of each DO signal. This protects both the simulator and the PLC from connection errors (short circuit). A value of 1k is sufficient for a correct reading via the DI input of the PLC.

DI1-DI8: digital input. LEDs with series resistors. The current drawn by one input for 24V DC is approximately 4.5 mA.

AO1-AO4: analogue outputs 0-10V and 0-20mA selectable by switches. With the potentiometer position at 100%, the voltage is equal to 10.5V and the current 21mA. This slight overdrive has been implemented intentionally. The minimum load resistance of the 0-10V output is 2kOhm. Below this value, the output starts to limit the output current. This ensures that when the 0-10V output is mistakenly connected to the 0/4-20mA input of the controller under test, it will not damage this input. The maximum load resistance of the 0-20mA output is 500Ohm. The open loop voltage is 11.8V. Thus, mistakenly connecting the 0-20mA output to the 0-10V input of the controller under test will not damage this input.

RTD1: PT100 sensor simulator. A 10-turn precision potentiometer with a value of 100Ohm. Connected in series internally with a 91Ohm precision resistor. The whole provides a resistance range of 91Ohm-191Ohm which corresponds to a temperature range of -23 to + 245 stC. Per revolution, there is a change in simulated temperature of approximately 26stC

RTD2: same operation as RTD1 but in this block it is possible to eliminate an additional series resistor by using a switch. The Rs position indicates a 91Ohm resistor in series and the Rs crossed out position indicates the bypassing of this resistor. This option offers two advantages:

(a) this allows very low negative temperatures to be simulated

(b) it is possible to connect two RTD1 and RTD2 blocks in series using an external bridge and create a single circuit to simulate a PT100 sensor with a maximum resistance value of 291Ohm while maintaining continuous control with two potentiometers. This corresponds to a temperature of approximately 530stC.

AI1, AI2: these are voltmeters/ammeters for visualising the status of the AO output of the controller under test. In the 0-10V position the circuit measures the voltage, the value is displayed in volts. The input resistance is several hundred kilohms. In the 0-20mA position, the circuit is an ammeter. The displayed value is in milliamps. The input resistance is then 100Ohm.

PO: rectangular wave generator. It is useful for pulse counting circuits. The amplitude of the waveform is approximately 22Vp-p. An LED labelled "Output" is connected to the generator output and flashes in sync with the output signal. There is a 1k/1W resistor in series with the generator output. This protects both the simulator and the PLC from connection errors (short circuit). A value of 1k is sufficient for a correct reading by the PLC input. The operating modes are selected by a 5-position rotary switch. Positions FR1-FR4 are the ranges of the frequency of the generated signal fluently varied by a potentiometer within the range.

OFF- generator turned off. Low state at the PO output.

FR1- Potentiometer position 0%- frequency f= 0.3Hz, duration of high state TH= 100ms, duration of low state TL= 3200ms.

Potentiometer position 100%- f= 5Hz, TH= 100ms, TL= 100ms.

FR2- Potentiometer position 0%- frequency f= 3Hz, duration of high state TH= 10ms, duration of low state TL= 320ms.

Potentiometer position 100%- f= 50Hz, TH= 10ms, TL= 10ms.

FR3- Potentiometer position 0%- frequency f= 30Hz, high state duration TH= 1ms, low state duration TL= 32ms.

Potentiometer position 100%- f= 500Hz, TH= 1ms, TL= 1ms.

FR4- Potentiometer position 0%- frequency f= 300Hz, high state duration TH= 0.1ms, low state duration TL= 3.2ms.

Potentiometer position 100%- f= 5kHz, TH= 0.1ms, TL= 0.1ms.

The frequency ranges "overlap" providing access to any value in the range of approximately 0.3Hz to approximately 5kHz.

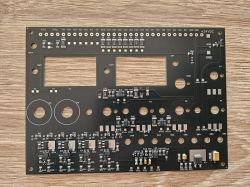

I made the board design in OSHWLAB, manufacturing with component assembly in JLCPCB.

This is what the TOP side of the board looks like

.

.

And this is the BOTTOM side

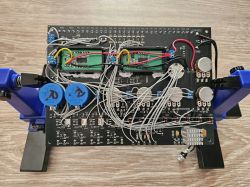

TOP side after installation of potentiometers, switches etc.

And the BOTTOM side after making the connections. Spaghetti but unfortunately unavoidable.

.

.

Greetings!

Cool? Ranking DIY