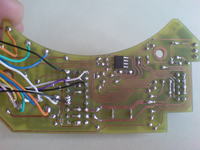

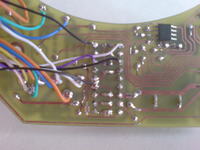

After applying the 5V voltage to 8, the motor driver's foot starts without any problems. I checked all the legs you asked for and there is tension on them. The motor controller stand is well soldered.

Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tamMatt_x89 wrote:After applying the 5V voltage to 8 the motor driver's foot starts without any problems. I checked all the legs you asked for and there is tension on them. The motor controller base is well soldered.

$regfile = "m128def.dat"

$crystal = 16000000

Config Pina.0 = Output

Config Pinb.5 = Output

Config Pinb.6 = Output

Config Pinb.7 = Output

porta.0=0

portb.5=0

portb.6=0

portb.7=0

Do

Set Portb.5

Wait 1

Set Portb.6

Wait 1

Set Portb.7

Wait 1

Set Porta.0

Wait 3

Reset Porta.0

Wait 1

Reset Portb.5

Wait 1

Reset Portb.6

Wait 1

Reset Portb.7

Loop