Thanks for the link

The question came from the fact that I am still a layman in this field.

The question came from the fact that I am still a layman in this field.

Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tamsniff wrote:Thank you very much for the answers.

4. What signal goes through the PA0 - MOTON port to this disk driver?

5. What is the power of your watch? Voltage - if TDA will not do any tricks - 5V, and a current of 2A should be enough?

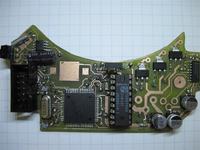

mateo238 wrote:1. And how to connect the motor with 4 lead out under the TDA5140 ??

2. Is it possible to obtain RPM regulation using the TDA system?

Sh44dow wrote:How old was your drive? What capacity?

My 40-gig IBM's plate crumbled like a glass when it touched the cornerIt also crumbles when cut with a handball.

I found an old plate from a dozen-year-old disk ~ 120MB (still with the "golden" layer from the outside) and cut out without any problem in it. Unfortunately, it is crooked like a sidewalk in the city and is not suitable..

I have a few more 9GB SCSI disks that I used to buy for a penny and I'm thinking about undressing one I would like to avoid unnecessary demolition so I need to determine if only newer disks are so fragile.

Press wrote:Nice idea and great performance.

But that's how I wonder how to make tips different in length ...

Anyone have an idea?