MAX232 can be used for programming uC but first you have to burn small program into ATMEGA which enables this functionality.

Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tampretzel wrote:Unfortunately, a colleague is wrongIn compiled batch to EEPROM there are color palettes to be displayed on the "clock face".

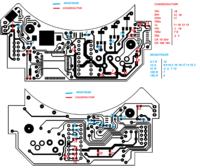

mnemonic wrote:Hello, I will refresh the subject a bit and present the modification of the watch:

.........

g_speed is a variable that changes like g_position, but with a different speed. You can subtract subtracting from g_position so that you do not run out of data to read from memory, you need to prepare and test your color tables properly.

5. Recording from a digital camera does not fully reflect the obtained effect.

kerat wrote:

Hi, I'm impressed by your craftsmanship and modification. I decided to make this clock and I was able to gather almost all parts. Recently I worked on my version of the PCB. Then I found on Youtube your mod and I thought would you be so kind as to share the software that run your clock?

Sorry for my english, a lot of google translate. Best Regards!

Milen

lugigann wrote:Hello everyone !

Please tell me the program run only with the loaded bootloader and the bootrst fusebit programmed ?

The controller does not respond to the command, it's as if it was not programmed.

On almost all the pins (exlus VCC, GND, XTAL, MOSI, MISO .....) I have 1.9 - 2v.

Dziękuję ! Wszystkiego najlepszego !