Eh... I've already ordered almost everything :(

Added after 8 [hours] 5 [minutes]: It's been over 1.5 years since your last entry, so I didn't expect you had anything else in stock.

I ordered the display and the rest along with the tips from RS-Components.

This is a very interesting topic and I'm surprised it's so little popular.

It turned out that Dirty rejected it because the size didn't match. I wrote to you privately.

You didn't respond, so I ordered a PCB from PCBWAY version 1.1, which has programming pins/pins.

They are already in Poland, I will receive them any day now.

I got

Updated for today..

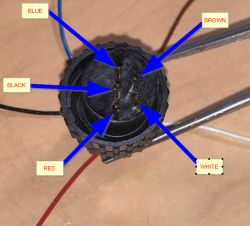

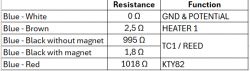

I've got it ready. It works and it seems to be OK, but if the mini-drive socket is bad, the contacts are weak or something else, I don't know, you will burn the tip. This happened to me twice. I managed to save the third one. Everything works, heats and regulates nicely, temperatures are consistent. I have a KTY82 in my stock and everything else. Today I was soldering for an hour, everything was fine, until at some point the display started going blank and the tip started turning red. I took it out in time. I know, it's my fault because I used an arbitrary socket (in a hurry), but in my opinion the design should provide for all possible options that may occur when inserting, removing or even damaging the mini jack socket.