I warmly welcome

Due to the fact that from time to time the topic of inspection microscopes in the "Do It Yourself" category appears here, I decided to present my solution for this device.

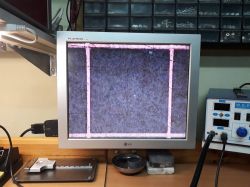

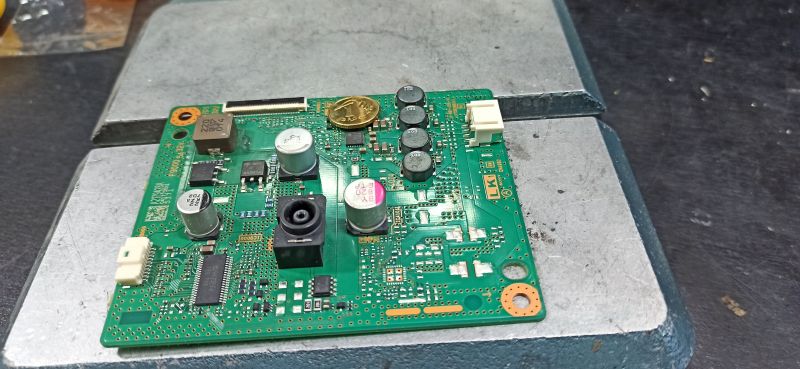

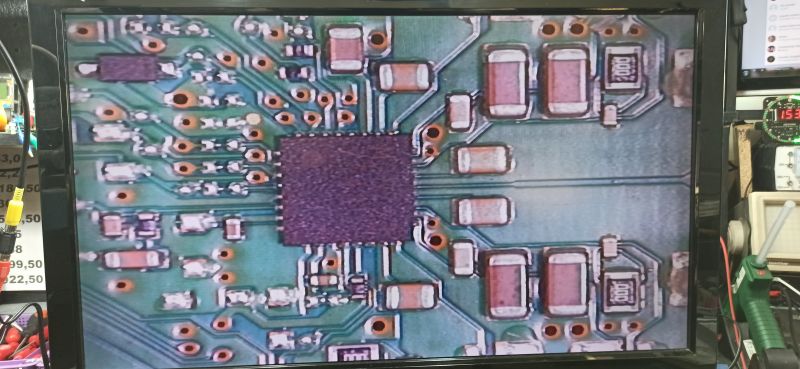

The design is not extraordinary and innovative, it is based on an industrial camera that I recovered from electro-waste, the webcam gives a video signal in color (I was even surprised that we throw away such things here).

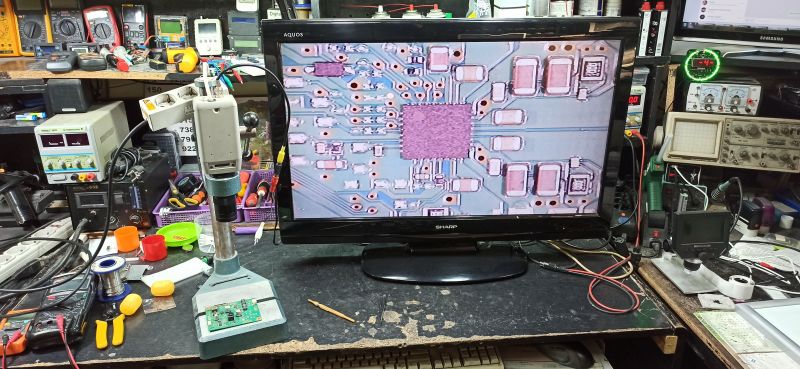

The camera output is typical for industrial cameras, the AV output is terminated with a BNC socket to display the video signal on a computer monitor due to the fact that CCTV monitors are for some reason much, much more expensive, I used a signal converter purchased on a Chinese portal. It has several inputs on board, including VGA, SVIDEO and industrial AV input and one VGA output, of course.

For me, it turned out to be practical enough, because I additionally connected the video signal from the computer to it with a standard VGA-VGA cable, but quite long, about 5m, and in case of the need, for example, to view the diagram that I currently have displayed on my computer monitor, the arrangement of components without detaching from the soldering iron, I switch the image signal source that interests me.

I won't elaborate on the functions that the converter has, I've had it for a long time and I don't really remember what parameters it has.

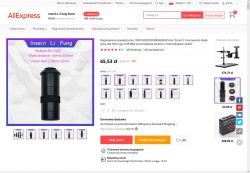

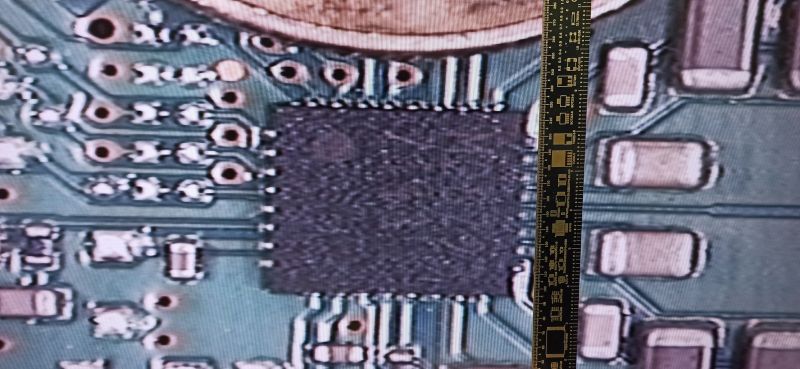

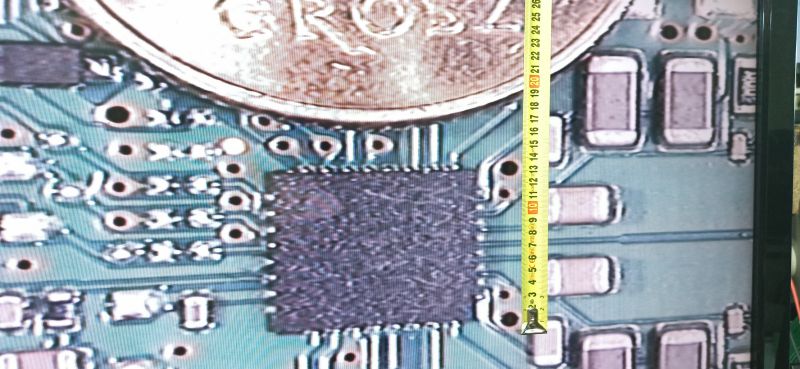

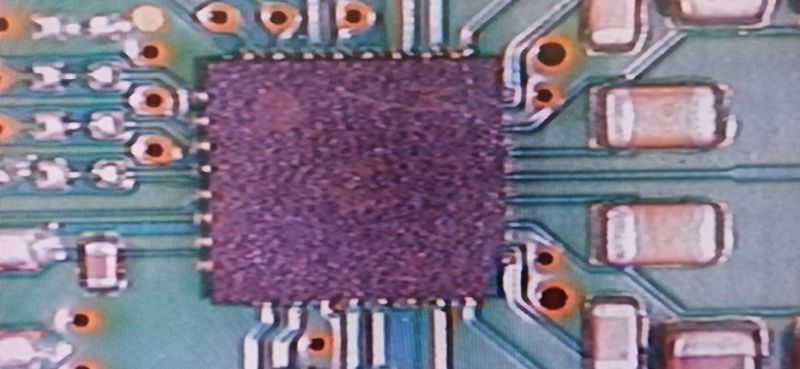

In the webcam itself, a C-Mount lens was replaced (of course also purchased on the Chinese portal), which allows me to enlarge the image 30 times, a better lens could be installed, but the price was about PLN 80, on the portal it was stated that a magnification of 100x.

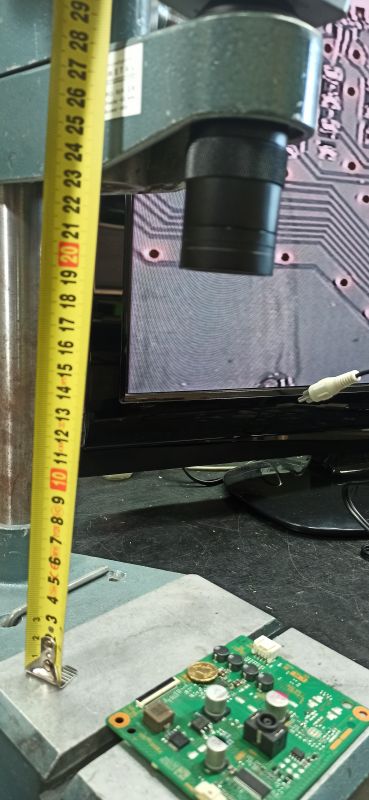

For the whole thing, I needed a tripod, on which I planned to mount the camera steadily, especially since it gained some weight with the new lens, but at first I had no idea for a good solution. In the place where the microscope was to be mounted, there was little space, because for the sake of convenience, I installed a shelf above the worktop for the instruments. I came up with the idea that I would install the articulated arm of the camera's boom on the underside of this shelf. It served me for a while, but it had a tendency to drop to its maximum reach, and that was how it was set up for work. Additionally, in the horizontal axis, the microscope was able to loosen, so that before each unfolding, all the locks had to be tightened very tightly, sometimes I had the impression that the threads would not withstand it.

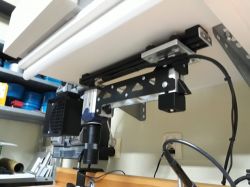

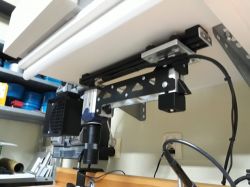

And recently I decided to solve this problem, I designed a new tripod in Fusion360, also screwed to the shelf.

The structure is based on one 20x40 mm V-slot profile, which serves as a horizontal guide, and one 40x40 profile, which is the rotary axis on which the microscope frame is mounted. The rotary axis has a bearing, in addition, I used a simple magnetic lock when setting the microscope to work, so that the system did not have a tendency to self-fold. The elements of the tripod, apart from the profiles and some small elements, were cut on a CNC plotter. The rest of the details are shown in the photos, on the GrabCAD portal where I have placed the CAD file of the structure, you can download it or watch it in 3D => https: // grabcad.com/library/inspection-microscope-stand-1

Due to the fact that from time to time the topic of inspection microscopes in the "Do It Yourself" category appears here, I decided to present my solution for this device.

The design is not extraordinary and innovative, it is based on an industrial camera that I recovered from electro-waste, the webcam gives a video signal in color (I was even surprised that we throw away such things here).

The camera output is typical for industrial cameras, the AV output is terminated with a BNC socket to display the video signal on a computer monitor due to the fact that CCTV monitors are for some reason much, much more expensive, I used a signal converter purchased on a Chinese portal. It has several inputs on board, including VGA, SVIDEO and industrial AV input and one VGA output, of course.

For me, it turned out to be practical enough, because I additionally connected the video signal from the computer to it with a standard VGA-VGA cable, but quite long, about 5m, and in case of the need, for example, to view the diagram that I currently have displayed on my computer monitor, the arrangement of components without detaching from the soldering iron, I switch the image signal source that interests me.

I won't elaborate on the functions that the converter has, I've had it for a long time and I don't really remember what parameters it has.

In the webcam itself, a C-Mount lens was replaced (of course also purchased on the Chinese portal), which allows me to enlarge the image 30 times, a better lens could be installed, but the price was about PLN 80, on the portal it was stated that a magnification of 100x.

For the whole thing, I needed a tripod, on which I planned to mount the camera steadily, especially since it gained some weight with the new lens, but at first I had no idea for a good solution. In the place where the microscope was to be mounted, there was little space, because for the sake of convenience, I installed a shelf above the worktop for the instruments. I came up with the idea that I would install the articulated arm of the camera's boom on the underside of this shelf. It served me for a while, but it had a tendency to drop to its maximum reach, and that was how it was set up for work. Additionally, in the horizontal axis, the microscope was able to loosen, so that before each unfolding, all the locks had to be tightened very tightly, sometimes I had the impression that the threads would not withstand it.

And recently I decided to solve this problem, I designed a new tripod in Fusion360, also screwed to the shelf.

The structure is based on one 20x40 mm V-slot profile, which serves as a horizontal guide, and one 40x40 profile, which is the rotary axis on which the microscope frame is mounted. The rotary axis has a bearing, in addition, I used a simple magnetic lock when setting the microscope to work, so that the system did not have a tendency to self-fold. The elements of the tripod, apart from the profiles and some small elements, were cut on a CNC plotter. The rest of the details are shown in the photos, on the GrabCAD portal where I have placed the CAD file of the structure, you can download it or watch it in 3D => https: // grabcad.com/library/inspection-microscope-stand-1

Cool? Ranking DIY