Hey,

thanks for this great work and detailed description of the adblue (disaster-)tank of Citroen.

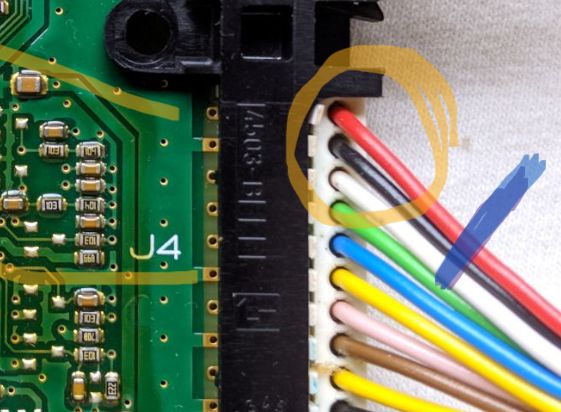

What kind of electric motor is it? With the number, which is printed on, I can't find anything. Does anyone know where I can get a replacement?

Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tammako122 wrote:>>20290653

https://www.elektroda.pl/rtvforum/posting.php...tvforum/posting.php?mode=editpost&p=20290653#

Other readings:

50.0°C - 3.93 kΩ

49.0°C - 4.07 kΩ

.

.

.

1,0°C - 24,90 kΩ

0,0°C - 25,90 kΩ

Measurements taken indicate that the sensor located directly on the heating plate is NTC 10,0 kΩ SMD thermistor which serves to protect the plate from overheating in the event that, for example, there is no urea in the tank. which is used to protect the plate from overheating if, for example, there is no urea in the tank and the heating plate starts to operate.

mako122 wrote:michal1226 wrote:If there is a problem with communication over CAN then why does the first 30s all information arrive via OBD connector to the diagnostic interface?

Maybe there is no communication problem just the tank after starting the car tests itself and the test does not pass!!! Then it sends information such as " It does not work properly, for example, I do not detect the circuit of heating urea such and such and please for safety turn me off!!!!! Unfortunately, without knowing the microprocessor software in the tank and its operating logic, it is difficult to say anything sensible. I am convinced that the tank does a check of its circuits and sends a message to the car's central computer.

What solution do I see?

If someone has access to a working tank it would be worth doing such exclusion tests.

Disconnect all sensors and heaters etc from the board. Connect the bare board itself, but 100% working, to the car and see if after 30s it drops voltage, if so, connect other peripherals and by deduction check what causes the voltage drop. In each circuit of urea heating there is a shunt to inform the tank computer whether the circuit has a break or short circuit. That is, the tank computer even monitors such things. It knows if a circuit is working properly or not. All it takes is for one heating circuit to draw too much current or to be short-circuited and this could already be the reason that the tank sends a command to the central computer "turn me off" because I have a faulty heater and cannot continue to work!!!

mitchcisco7 wrote:..

Hi, has anyone been able to find a new pump motor? The bushings in my current engine have broken and the motor has seized.

mitchcisco7 wrote:..

Hi, has anyone been able to find a new pump motor? The bushings in my current engine have broken and the motor has seized. I was wondering if there is a replacement motor available that would work instead? The code on the motor doesn't refer to anything on Google (that I can find).

Any help on this would be greatly appreciated.

Thanks.

.

.

.

.

.

.