Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tammelas wrote:I'll see what I have in stock on Monday, see if I can find a good one, we'll think about it

mako122 wrote:bbmax wrote:I'm wondering what fix tool and flasher with tank

Can you write more about it?

Any links?

Price?

Documentation?

bbmax wrote:mako122 wrote:bbmax wrote:I'm wondering what fix tool and flasher with tank

Can you write more about it?

Any links?

Price?

Documentation?

well, the price is a downside here because at the dealer 950 euros for the programmer and 280 eu for a piece of cablewith plug

partial documentation...

.

.

.

.

.

.

st.sitarz wrote:Good morning Hello everyone. Great respect for the work done and documentation.

I have a question, maybe someone has a quick connector for sale, or rather a gray cotter pin that I marked in the picture. This is the connector of the AdBlue output pipe from the tank to the injector (Peugeot 5008 II). Thank you in advance.

st.sitarz wrote:Good morning Hello everyone. Great respect for the work done and documentation.

I have a question, maybe someone has a quick connector for sale, or rather a gray cotter pin that I marked in the picture. This is the connector of the AdBlue output pipe from the tank to the injector (Peugeot 5008 II). Thank you in advance.

ZlPu wrote:But the pump still didn't work.

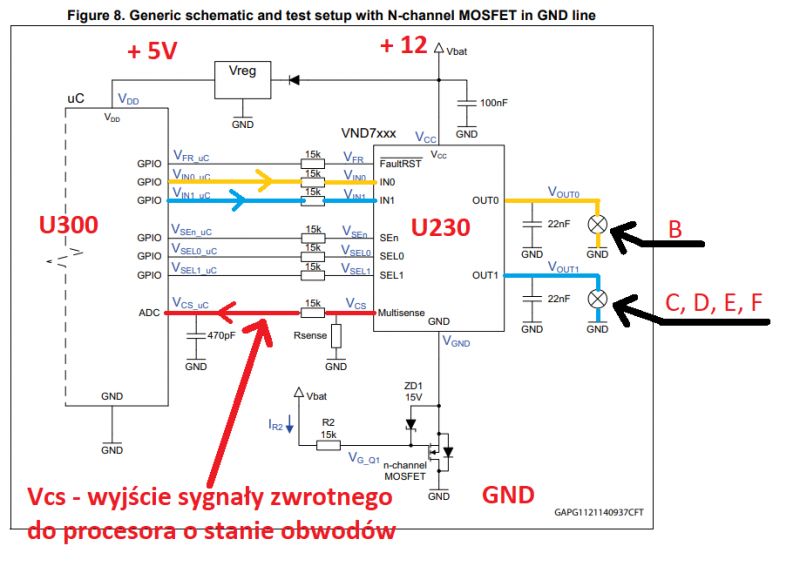

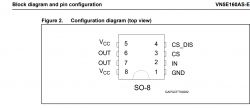

As another error, I detected one of the MosFet transistors (H-bridge). The system must always be turned off empty (tank and wires must always be empty) to prevent freezing and crystallization of the fluid in the system. Therefore, the direction of rotation changes (H-bridge)

bbmax wrote:

mako122 wrote:I renew my request:

I am looking for a pressure sensor (probably this sensor has a commercial designation: HM8500C SCR Urea Pressure Sensor) https://www.ever-smart.com/product/99.html

In order to take measurements and develop a topic about this sensor.

I have a measuring stand prepared, but the sensor I have is probably damaged.

If anyone has such a sensor, please let me know. I can buy such a sensor or return it after testing.

Of course, I'm not doing these tests just for myself. I will post all the information and results of measurements in this thread.

Model No.: HM8500J place of origin: China use: Pressure Sensor principle: Resistance Sensor Output: Analog Sensor Amplifier type: Analog Output jack: Analog technology: Resistive

wrzosek wrote:My solenoid valve only opens at 8v. Is it good?

wrzosek wrote:I did the tests yesterday after removing the pump valve accumulator assembly.

Pump power supply 12v, solenoid valve 4.8 (three fingers) - the pump is spinning, the valve is not open.

Pump 12v power supply, solenoid valve removed - the pump sucked water very quickly.

Today, using a power supply with adjustable voltage, I measured that the valve is fully open at 7 volts.

What voltage does the control board provide to the solenoid valve?

wrzosek wrote:solenoid valve 4.8 (three fingers) - the pump is turning, the valve is not open.