Hi.

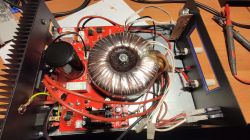

I made a power supply, nothing innovative because it is a good construction that has been going through the internet for over a dozen years.

With this construction, I put more emphasis on the design (at least I think so). Despite quite a long thought process, this power supply was not without mistakes. Fortunately, these errors do not force any major changes, such as cutting paths, etc.

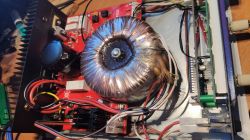

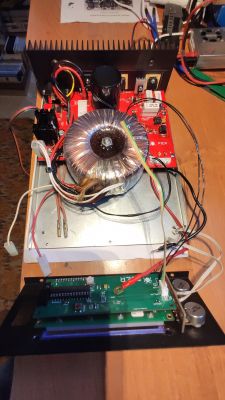

It started with the fact that I fell into my hands ups and in it quite a large transformer, 2x15V ~ with power I guess 650W. Additionally, it has a 22V ~ winding used for an auxiliary power supply. Designation of the transformer S 650/4 R11.

As I had no idea where to use it, it fell on the power supply, there are never too many of these. I had no experience with other designs, so I focused on the Electronic Lab.

I spent a lot of time on the power supply board. I have equipped the power supply with a transformer winding switching system and a 12 and 5V auxiliary power supply. The rest is unchanged, except for changing the transistor controlling the output stage and adding a second power transistor. Such modifications are also standard in this design.

The mistakes I made on this board were the wrong footprint of the BD139 transistor, which meant that its legs had to be changed.

The rest are a few mislabeled resistors. Apparently nothing but I felt nervous when starting up.

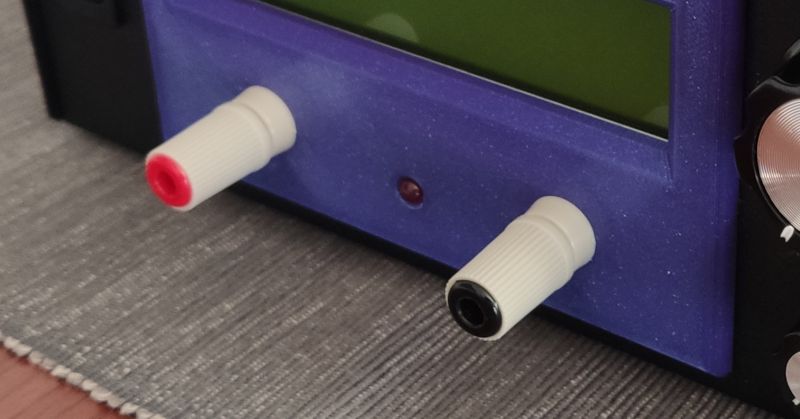

The meter is my design. It works, but it is still under development. So far, there is no option to calibrate indications or any configuration. The meter has the ability to control the fan, so far as you can see there is no fan, it only shows the temperature of the heat sink. On this PCB, I placed the connectors too close, so they do not fit next to each other and some wires had to be soldered directly into the PCB.

The meter is built on a large 2x16 display.

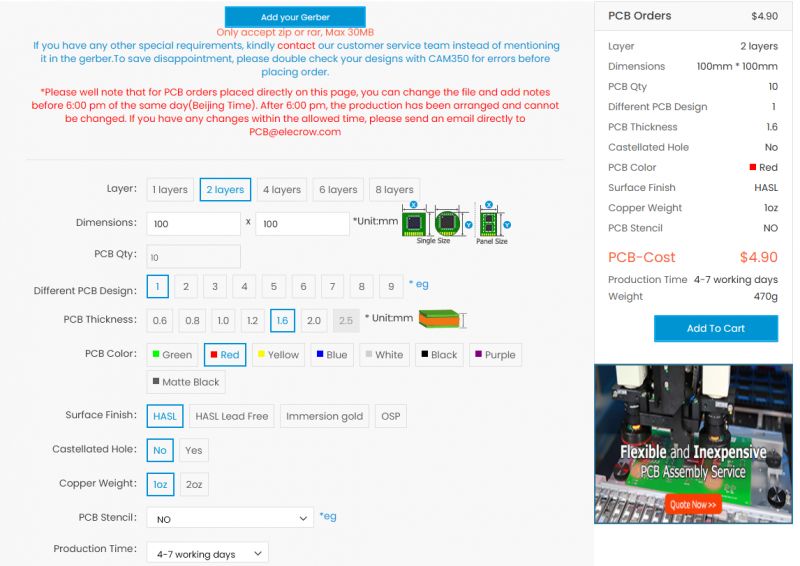

As you can see, the tiles are made in Asia, JLCPCB to be precise.

Everything is packed in the housing marked E208B. Very nice box, stiff. I was able to buy a heat sink that fits the housing perfectly, I just had to cut off a piece for the power socket.

The front panel, due to the dimensions of the housing and the display used, seems a bit non-functional, especially with the knobs, but I have no problem with operating them. Maybe the purple overlay on the LCD does not fit a bit, but it was just one that was available from the printer at the time. Yes, this plastic is specially designed and printed for this project. I was always attracted to the poor display in the housing. No descriptions on the panel because, first of all, I have no idea yet, and second, what should I describe here?

During the short tests, the power supply was fine. If I wanted to load it longer with maximum currents, I would have to think about another series resistor. The current 2x 0.47om 5W after three minutes with a current of 7A has a temperature close to 80 degrees. Bridge and heat sink transistors even do it. If it is something, I can add a fan.

The op-amps used still need to be explained.

In the design phase, I did not take into account the higher than acceptable voltage of the amplifiers from the second tap of the transformer. I thought, I advised on the forum how to figure it out. A quick solution would be to replace the amplifiers with those that can be powered with higher voltage, but the availability and prices of such cubes are not encouraging. The second option would be to add a stabilizer for op-amps, but this is an addition to the circuit and cutting paths.

In the end, the usual UA741 were left, yes, I know they work with too high supply voltage, but during the tests nothing happened with them. They work steadily and I have not noticed excessive heating. But of course, I do not recommend imitating.

Feel free to comment.

Greetings Piotr.

Cool? Ranking DIY