Soon in Elektroda.pl gadgets A kit will appear that allows you to build a simple regulated power supply with voltage and output current readout. Inverter module descriptions DC / DC buck 9A 300W 1.2V-35V and a panel current and voltage meter DSN-VC288 can be found at elektroda.pl. After completing the set with a direct current source (e.g. unnecessary laptop power supply, transformer with rectifier and capacitor), you will get a simple regulated power supply. For the convenience of adjustment, the assembly potentiometer can be replaced with a multiturn potentiometer equipped with a knob.

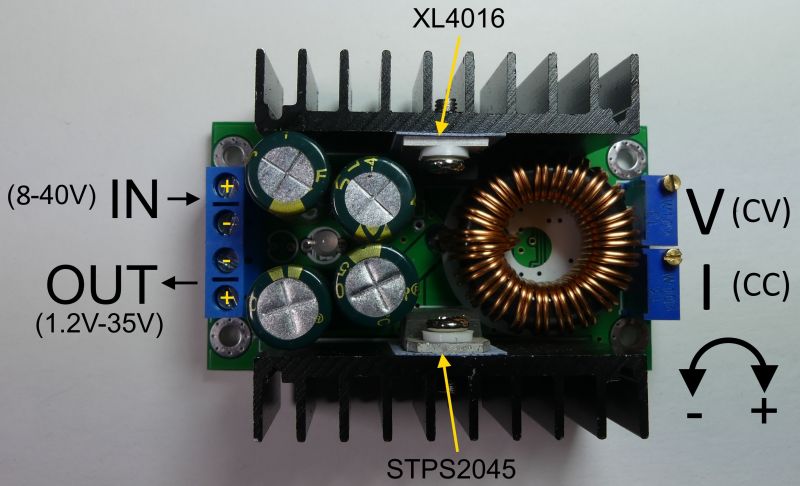

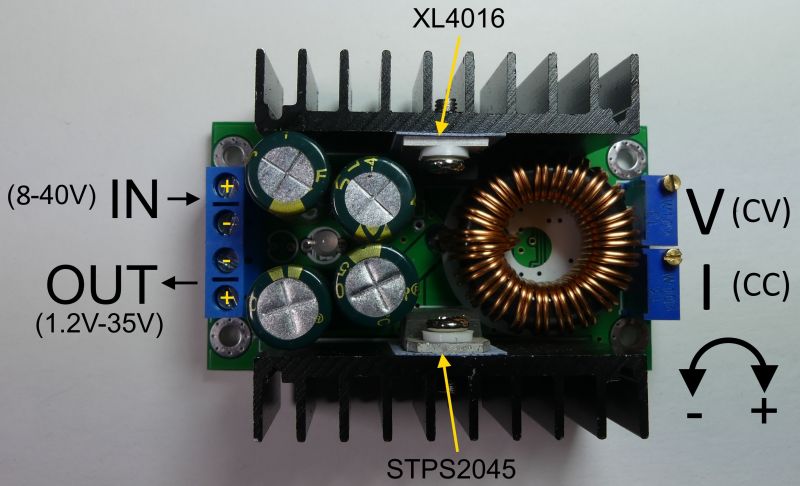

The DC / DC converter, apart from voltage regulation (CV operation), also allows for current limit regulation or CC operation. The impulse converter is based on the XL4016 chip and enables voltage regulation in the range of 1.2V-35V, maximum output current 9A. Input voltage in the range of 8-40V. Details can be found in the description: https://www.elektroda.pl/rtvforum/topic3434421.html

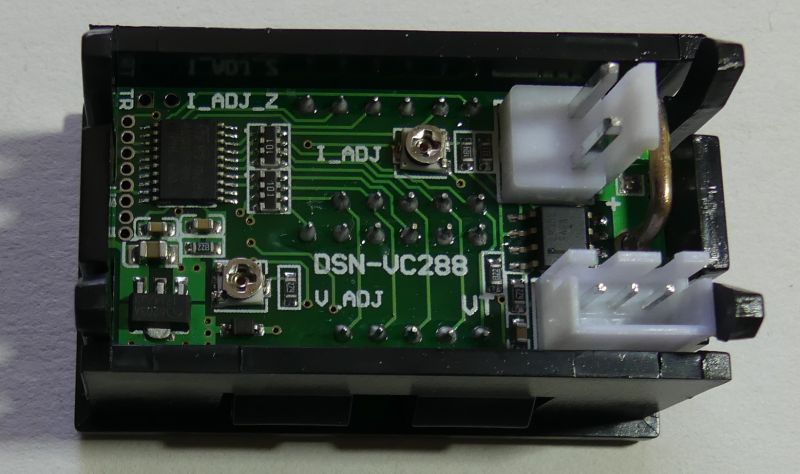

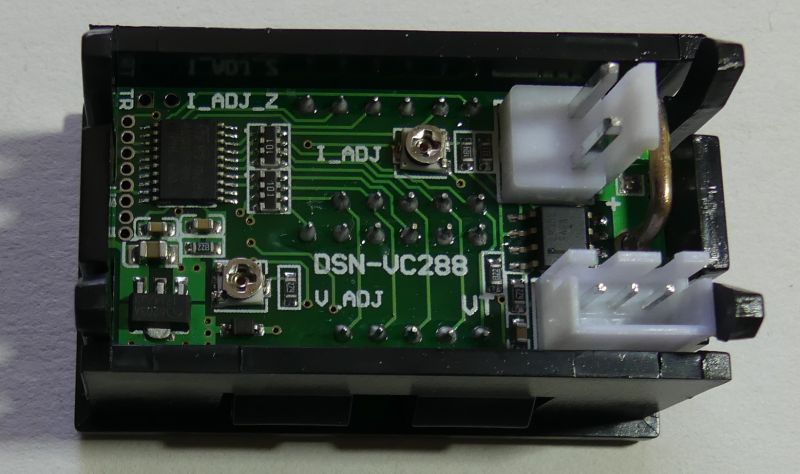

The panel meter has a moderate accuracy of indications, we can try to improve it using mounting potentiometers placed on the module's board.

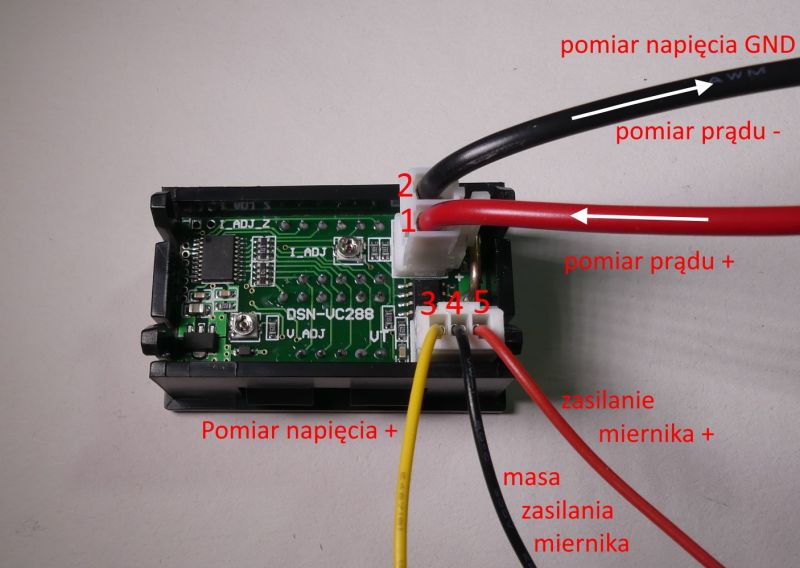

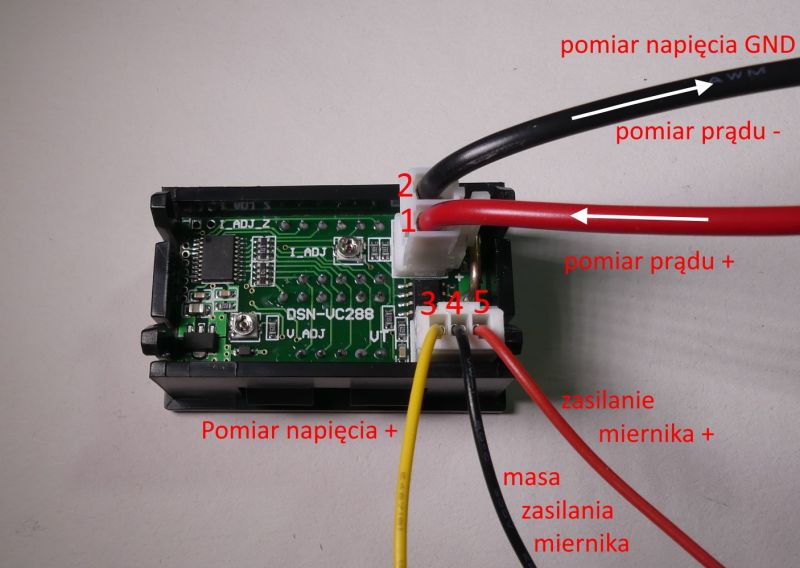

The LED panel meter can be powered from a separate voltage source (or e.g. from an isolated AIMTEC DC / DC converter). Supply voltage is applied to wires 4 (GND) and 5 (+). When powered by 12V, the system consumes a current of about 20mA. Apply the voltage measured in relation to the wire 2 (GND) on the wire 3. Depending on the source, module suppliers provide the permissible supply voltage in the range of 4.5-24V. The system can be powered from the measured voltage or from the voltage at the converter input, then the wire 4 is left unconnected (the mass of the system is on the wire 2).

It is important that the voltage supplying the meter does not exceed 24V (other sources indicate 28V or 30V). The converter can work with voltages as high as 35-40V. In such a situation, a stabilizer should be placed in the power supply circuit of the meter (wire 5), e.g. + 12V, the wire 4 is not connected.

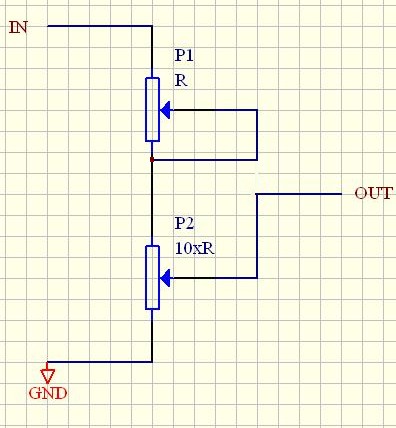

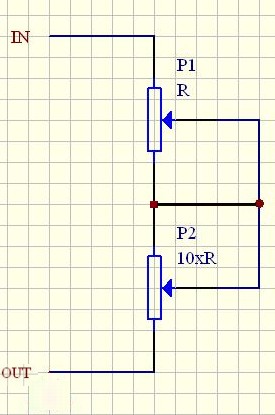

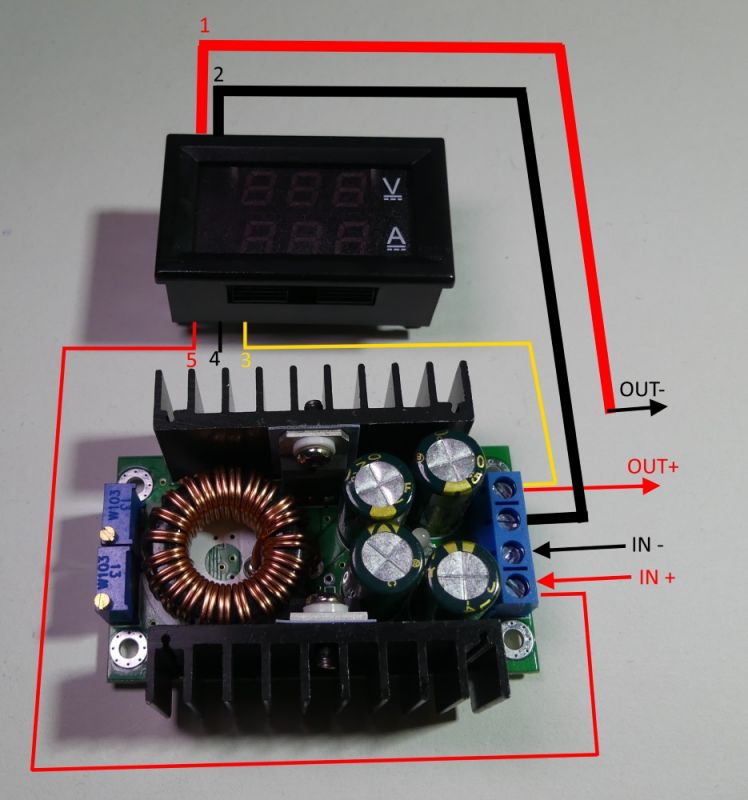

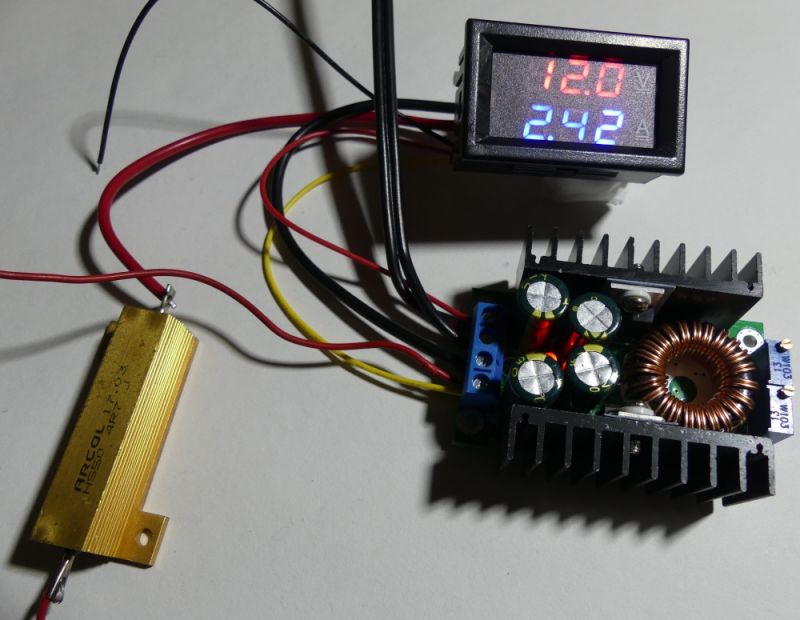

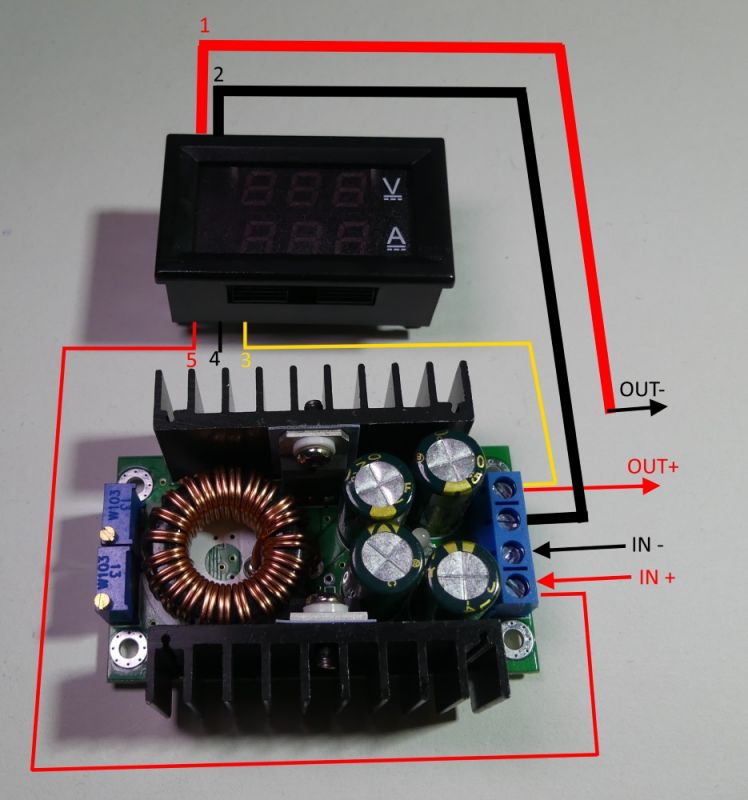

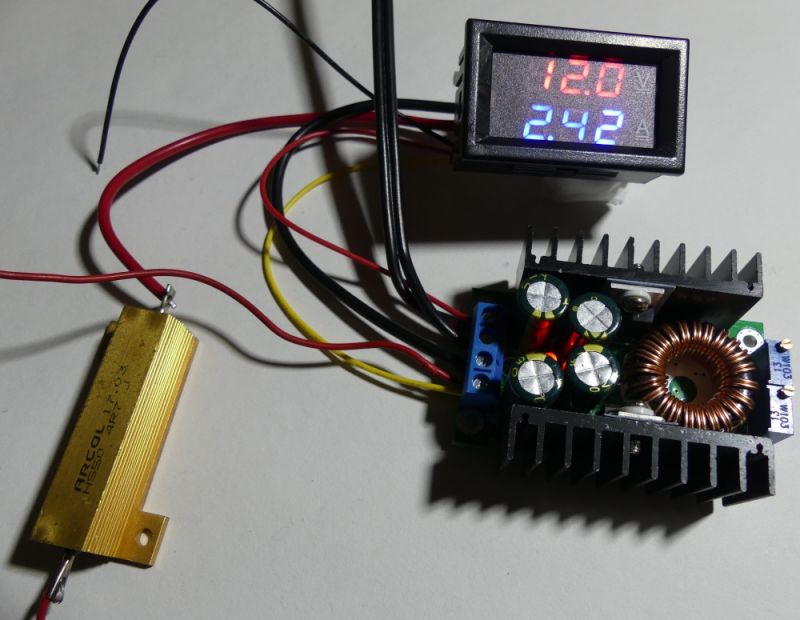

The current is measured in the circuit of the measuring resistor on leads 1 and 2. Below is a diagram of the module connection (for supply voltages up to 24V) and a view of the practically connected modules. A 4.7om resistor simulating the receiver is connected to the output.

It is worth paying attention to the set's output cable, which acts as the output GND. This is the red lead of 1 meter. Be careful not to confuse the polarity as the red wire is usually + power. A comprehensive description of the panel meter can be found here: https://www.elektroda.pl/rtvforum/topic3444499.html

It is worth completing the whole with a housing and replacing both mounting potentiometers of the converter for voltage regulation and current limitation, with multi-turn potentiometers with knobs mounted on the front panel of the housing. It is worth to lead the output voltage to the terminals mounted in the housing. The source of voltage can be a traditional transformer, rectifier and a ripple smoothing capacitor, but you can also use a recycled switching power supply, e.g. from a laptop, printer, etc. The built power supply will have its limitations, but it can be useful in many workshops for "rough" measurements and powering less demanding circuits.

Let me know what results can be obtained with the use of the presented set.

The DC / DC converter, apart from voltage regulation (CV operation), also allows for current limit regulation or CC operation. The impulse converter is based on the XL4016 chip and enables voltage regulation in the range of 1.2V-35V, maximum output current 9A. Input voltage in the range of 8-40V. Details can be found in the description: https://www.elektroda.pl/rtvforum/topic3434421.html

The panel meter has a moderate accuracy of indications, we can try to improve it using mounting potentiometers placed on the module's board.

The LED panel meter can be powered from a separate voltage source (or e.g. from an isolated AIMTEC DC / DC converter). Supply voltage is applied to wires 4 (GND) and 5 (+). When powered by 12V, the system consumes a current of about 20mA. Apply the voltage measured in relation to the wire 2 (GND) on the wire 3. Depending on the source, module suppliers provide the permissible supply voltage in the range of 4.5-24V. The system can be powered from the measured voltage or from the voltage at the converter input, then the wire 4 is left unconnected (the mass of the system is on the wire 2).

It is important that the voltage supplying the meter does not exceed 24V (other sources indicate 28V or 30V). The converter can work with voltages as high as 35-40V. In such a situation, a stabilizer should be placed in the power supply circuit of the meter (wire 5), e.g. + 12V, the wire 4 is not connected.

The current is measured in the circuit of the measuring resistor on leads 1 and 2. Below is a diagram of the module connection (for supply voltages up to 24V) and a view of the practically connected modules. A 4.7om resistor simulating the receiver is connected to the output.

It is worth paying attention to the set's output cable, which acts as the output GND. This is the red lead of 1 meter. Be careful not to confuse the polarity as the red wire is usually + power. A comprehensive description of the panel meter can be found here: https://www.elektroda.pl/rtvforum/topic3444499.html

It is worth completing the whole with a housing and replacing both mounting potentiometers of the converter for voltage regulation and current limitation, with multi-turn potentiometers with knobs mounted on the front panel of the housing. It is worth to lead the output voltage to the terminals mounted in the housing. The source of voltage can be a traditional transformer, rectifier and a ripple smoothing capacitor, but you can also use a recycled switching power supply, e.g. from a laptop, printer, etc. The built power supply will have its limitations, but it can be useful in many workshops for "rough" measurements and powering less demanding circuits.

Let me know what results can be obtained with the use of the presented set.

Cool? Ranking DIY