Hello.

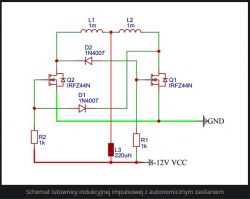

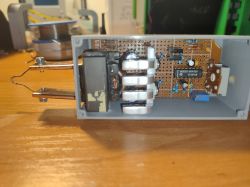

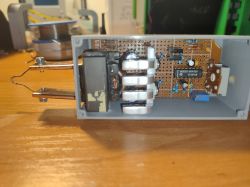

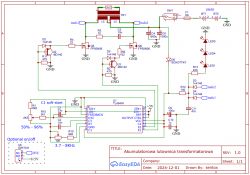

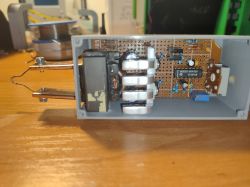

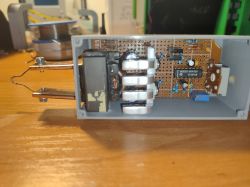

I used to really like the rechargeable soldering iron from this post: https://www.elektroda.pl/rtvforum/topic3303762.html and recently stated that I would attempt my own build. I already had all the parts recycled, the only thing missing was a flat bar for the secondary winding but this was found. The first prototype was according to the diagram from the link, but it didn't work very well, the zener diode (in my case a B-E transistor) got very hot and there was a lot of power loss. Well, but since I had a tl494 from an old ATX I figured I'd do it again only push-pull this time. It worked much better, the heatsink from the transistors is cold, the power is not missing.

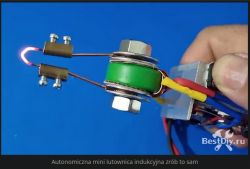

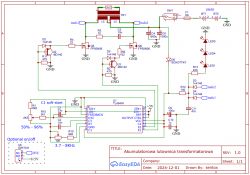

The operating frequency is 4Khz. The transformer is from an atx power supply and is probably ~1.2cm2 in cross section. The transformer generates its own power for the controller, the push-pull topology doubles the voltage on the primary side so it works great for us if the supply voltage is low. We have about 9-12V on the controller. The whole circuit requires at least 7V to start, below this something works, but the keys do not open fully and it is not able to generate a higher voltage to start. The trip threshold can be lowered by replacing silicon diodes with schottky diodes and/or transistors with a lower opening voltage. In theory the tl494 has undervoltage protection but something this piece of mine works even at <6V just produces some impaired waveform. But once it fires it works and even goes below 6V. There is a hole on the back of the case to adjust the power by changing the PWM fill. The blade is 0.75mm wire. The flat bar is 15x3mm, 12cm long. Because of the size and the material, the loss from conduction is negligibly small, but the loss from heat removal from the mainsail is already quite considerable and it heats up with continuous operation. If I were to make a second one, I would rather aim for an aluminium flat bar, I would make it longer and it would be even lighter and wouldn't pick up heat from the mainsail as much.

I made the winding from the kind of wire I had, the primary atx I think, a bit too thin but that's hard, it works. I measured twice 15 turns and at the output I have ~0.5V and all in all this is still too much, the mains only has 0.25V. And as you know twice the voltage requires 4 times less resistance to get the same power. So the blade needs to be quite thin, the one I have now is still a bit too thick and I need to have the power twisted. But too thin a blade will be too soft so it's not so easy to adjust. The problem with a heavy load(read thick/short arrowhead) is big voltage spikes on the transistors, up to 70V. For higher power you would need to improve the snubber network , you can add zeners to the transistors.

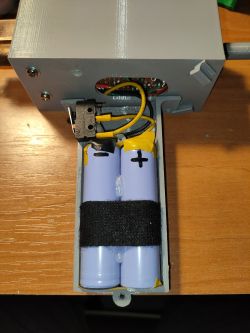

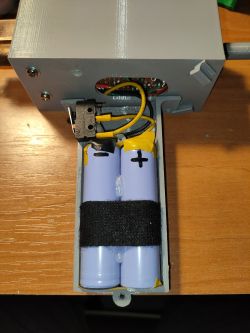

The current on the secondary is between 50 and 80A. The power supply is cells from a stripped Bosch hoover battery, they still have 1.8ah and a resistance of 35mR. The final weight is 300g. I still plan to add a power switch and a module to charge the battery when the stuff arrives from china. In the picture with the oscilloscope is the waveform on the flat iron at partial power. In the video he is testing the soldering iron at full power on a small heatsink.

.

.

.

.

.

I used to really like the rechargeable soldering iron from this post: https://www.elektroda.pl/rtvforum/topic3303762.html and recently stated that I would attempt my own build. I already had all the parts recycled, the only thing missing was a flat bar for the secondary winding but this was found. The first prototype was according to the diagram from the link, but it didn't work very well, the zener diode (in my case a B-E transistor) got very hot and there was a lot of power loss. Well, but since I had a tl494 from an old ATX I figured I'd do it again only push-pull this time. It worked much better, the heatsink from the transistors is cold, the power is not missing.

The operating frequency is 4Khz. The transformer is from an atx power supply and is probably ~1.2cm2 in cross section. The transformer generates its own power for the controller, the push-pull topology doubles the voltage on the primary side so it works great for us if the supply voltage is low. We have about 9-12V on the controller. The whole circuit requires at least 7V to start, below this something works, but the keys do not open fully and it is not able to generate a higher voltage to start. The trip threshold can be lowered by replacing silicon diodes with schottky diodes and/or transistors with a lower opening voltage. In theory the tl494 has undervoltage protection but something this piece of mine works even at <6V just produces some impaired waveform. But once it fires it works and even goes below 6V. There is a hole on the back of the case to adjust the power by changing the PWM fill. The blade is 0.75mm wire. The flat bar is 15x3mm, 12cm long. Because of the size and the material, the loss from conduction is negligibly small, but the loss from heat removal from the mainsail is already quite considerable and it heats up with continuous operation. If I were to make a second one, I would rather aim for an aluminium flat bar, I would make it longer and it would be even lighter and wouldn't pick up heat from the mainsail as much.

I made the winding from the kind of wire I had, the primary atx I think, a bit too thin but that's hard, it works. I measured twice 15 turns and at the output I have ~0.5V and all in all this is still too much, the mains only has 0.25V. And as you know twice the voltage requires 4 times less resistance to get the same power. So the blade needs to be quite thin, the one I have now is still a bit too thick and I need to have the power twisted. But too thin a blade will be too soft so it's not so easy to adjust. The problem with a heavy load(read thick/short arrowhead) is big voltage spikes on the transistors, up to 70V. For higher power you would need to improve the snubber network , you can add zeners to the transistors.

The current on the secondary is between 50 and 80A. The power supply is cells from a stripped Bosch hoover battery, they still have 1.8ah and a resistance of 35mR. The final weight is 300g. I still plan to add a power switch and a module to charge the battery when the stuff arrives from china. In the picture with the oscilloscope is the waveform on the flat iron at partial power. In the video he is testing the soldering iron at full power on a small heatsink.

.

.

.

.

Cool? Ranking DIY