More LIGHTNING and SUPERVISION.

Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tam

coorass wrote:I connected it to domoticz, I wrote 2 scripts to turn the stove on and off from the domoicz level - tested and works

Quote:I have a question, how did you read that this byte is responsible for turning the boiler on or off?

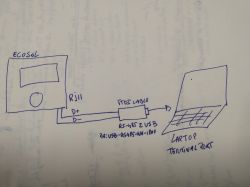

domadm wrote:I have a connection using ESP8266 + MAX, but unfortunately there is a problem, because communication works well for me only one way, i.e. I can receive data. It's probably a software issue, but what I have, esp-link, works like that with my RS485 interface.

I think now I would buy a ready RS485-Wifi interface on aliexpress and the problem should be taken care of.

curl -D- -u admin:admin http://192.168.10.8/econet/regParams

HTTP/1.1 200 OK

Content-Type: application/json

Transfer-Encoding: chunked

Date: Fri, 13 Nov 2020 23:04:15 GMT

Server: lighttpd/1.4.35

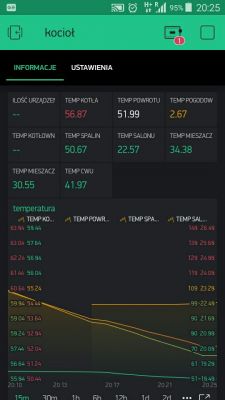

{"settingsVer":22897,"editableParamsVer":37558,"schedulesVer":5,"remoteMenuVer":{},"currentDataParamsEditsVer":0,"curr":{"thermostat": 1, "pumpCOWorks": true, "ecoSterMode2": 255, "ecoSterMode3": 255, "ecoSterMode1": 2, "mixerPumpWorks4": false, "mixerPumpWorks5": false, "mixerPumpWorks6": false, "ecoSterContacts1": true, "mixerPumpWorks2": true, "ecoSterContacts3": false, "statusCWU": 0, "fuelLevel": 86, "fanPower": 10.0, "tempBack": 40.838577270507812, "mixerTemp1": 46.876754760742188, "mixerTemp3": null, "mixerTemp2": 25.875900268554688, "mixerTemp5": null, "mixerTemp4": null, "mixerTemp6": null, "pumpCirculation": true, "ecoSterDaySched1": false, "pumpCWUWorks": false, "tempCOSet": 61, "contactGZC": false, "fuelStream": null, "transmission": 4, "mode": 3, "tempCWU": 47.68017578125, "tempExternalSensor": 4.3133015632629395, "ecoSterTemp3": null, "ecoSterTemp2": null, "ecoSterTemp1": 22.526351928710938, "ecoSterNumber": 3, "tempCO": 62.091094970703125, "pumpCO": true, "mixerPumpWorks1": true, "contactGZCActive": false, "statusCO": 0, "ecoSterContacts2": false, "ecoSterDaySched2": false, "ecoSterDaySched3": false, "mixerPumpWorks3": false, "pumpFireplace": false, "pumpSolar": false, "mixerSetTemp4": 34, "mixerSetTemp5": 34, "mixerSetTemp6": 34, "pumpSolarWorks": false, "mixerSetTemp1": 45, "mixerSetTemp2": 26, "mixerSetTemp3": 34, "pumpCWU": true, "boilerPowerKW": null, "tempCWUSet": 51, "pumpCirculationWorks": false, "boilerPower": 0, "tempFlueGas": 59.930408477783203, "pumpFireplaceWorks": false, "tempFeeder": 30.449920654296875, "ecoSterSetTemp2": null, "ecoSterSetTemp3": null, "ecoSterSetTemp1": 23.399999618530273}}