ksik wrote:

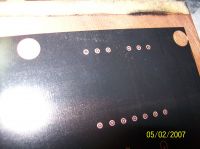

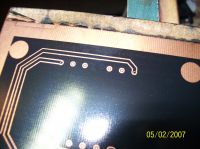

Did you correct something with a pen before throwing it in the etcher, because the pictures show that the paths are even and not ragged, and in addition large areas of copper are also undamaged until it is impossible that such a good toner is not bitten.

Pozdr.

I do not know what kind of toner, because I bought this printer about 5-6m ago and the company I bought in does not speak (maybe it does not exist anymore). I am not a chemist, but who knows whether the cause is not in some degree also the primer, or silicone (maybe react with each other). I did not have too much time and the problem with buying xylene in my area, so far I do not know the solvent.

As for the correction, they were corrected (not counting the sides, because I wanted to widen the circuit on the perimeter of the plate), in three areas (approximately 2x3 cm), but because a bit less toner left them in the drum (I did not want to let go print again) and I preferred to improve the pen for sure. I print the printout and sometimes it is so that the dust-bound dust (these are microns, but under the light) looks like the uncoated copper surface. There were many such eyes (dust), so I took the risk of etching to see one hundred percent, whether it is connected to dust as I wrote earlier, or not the toner (luckily, my assumptions have worked). In general, if only the print is even, there are no problems with undercoating.