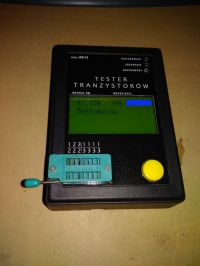

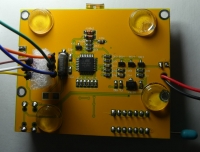

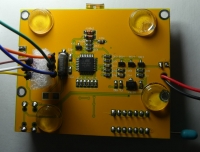

In the topic about the component tester LCR M328 Information about the possibility of changing the microcontroller firmware has appeared. I decided to check it in practice, despite the risk of breaking the device. Since the last tests, I have secured the LCD against falling out with a thermal glue and secured with a piece of stiff foil a flexible tape connecting the LCD with the board.

The software and documentation of the microprocessor tester can be found here:

https://www.mikrocontroller.net/svnbrowser/transistortester/

I suspect that all available LCR testers have software based on these sources.

We click "Download GNU tarball" and extract the content (e.g. using 7zip).

We will use the source code to work with Atmel Studio 7.

After installing the Atmel Studio 7 environment, select:

File -> New -> GCC C Executable Project, select the ATMEGA328P microcontroller and create a project with the selected name in the selected location.

We copy all files from the directory with unpacked contents \ Software \ trunk \

to the directory of the created Atmel Studio project (where the .cproj file is),

then we agree to replace main.c.

Copy the "fonts" and "mega328_st7565" directories from the \ Software \ trunk \ directory to the project directory.

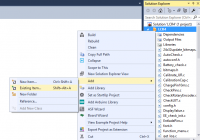

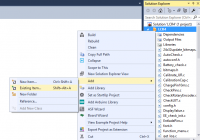

Right-click on the project name in the solution explorer window and select:

Add-> Existing items let's add all * .ci * .h files

Select project-> properties, select use external makefile and select the Makefile file from the "mega328_st7565" directory, in the project directory.

In the Makefile file we change:

UI_LANGUAGE = LANG_ENGLISH on UI_LANGUAGE = LANG_POLISH (if we want Polish menu)

CFLAGS + = -DLCD_ST7565_H_OFFSET = 4 per CFLAGS + = -DLCD_ST7565_H_OFFSET = 0 (image shift)

CFLAGS + = -DLCD_ST7565_V_FLIP = 1 per CFLAGS + = -DLCD_ST7565_V_FLIP = 0 (vertical flip)

CFLAGS + = -DLCD_ST7565_H_FLIP = 1 per CFLAGS + = -DLCD_ST7565_H_FLIP = 0 (level reversal)

I also experimentally turned on:

CFLAGS + = -DWITH_UJT (Option WITH_UJT enables additional tests for UJT (UniJunction Transistor))

It's worth experimenting with the Makefile by reading the descriptions and documentation in \ Dock \ tags \ english

To generate files to be placed in the microcontroller's memory, select:

We choose Build-> Build Solution.

We should receive a message:

========== Build All: 1 succeeded, 0 failed, 0 skipped ==========

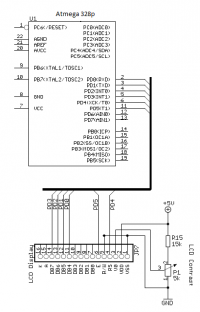

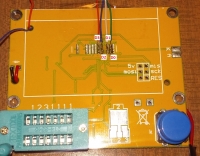

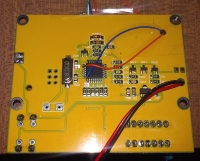

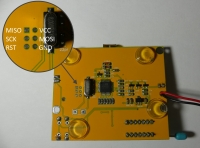

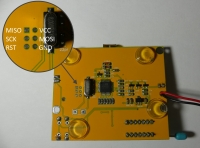

After completing the compilation, go to the "mega328_st7565" directory in the project directory, there is the TransistorTester.hex file (flash memory content) and TransistorTester.eep (eeprom content). Place both files in the memory of the ATMEGA328P microcontroller using the selected ISP programmer. I used AVRISP MKII and software from AtmelStudio environment. To connect to the ISP connector in the tester, I used the connecting cables for the contact plate. The photo below shows the pinout of the connector.

For the time of programming, we lock the button that turns on the device (e.g. with a clothes peg) to ensure continuous power supply of the microcontroller.

If everything goes well, the tester will greet us with messages in Polish:

We put our own logo.

Perhaps logo placement is not some super ambitious and necessary task, but it is a good way to start playing with tester code. We have an area of 128x32 black and white pixels at our disposal (during the ongoing test). We'll write each pixel as a bit in a byte, and that takes 512B in a 512-element array. Each byte will be a vertical 8-pixel dash starting at the top of the x-coordinate of the LSB bit of the array element. After reading as many elements as the image width is (in our example 128), we read the next bar at the y-greek coordinate by 8 pixels.

If we care about the logo and limit the memory consumption, we can think about a simple "compression", for example saving the coefficient of start and end lines horizontally or vertically instead of data for all pixels, for some pictures it will save memory.

The black and white elektroda.pl logo from the home page is saved to a PNG file with a resolution of 128x32:

With a simple python code, we convert a PNG file into an array, in which each bit corresponds to a lit or unlit pixel on the LCD. We set the height and width of the PNG file so that they are equal to the power of 2. For a 128x32 image we will have 128x (32/8) = 512 element array, a single element of the array will be a byte. To write the codes, we use the knowledge gained about python and png here:

Will the Sun clear the EPROM?

Quickly written python 3 code will turn the PNG file into an array of bytes:

[syntax=python]from PIL import Image

i = Image.open("logo.png")

xx=i.width

yy=i.height

print("szerokosc: "+str(xx)+" wysokosc: "+str(yy))

if xx>128:

print("Szerokosc wieksza od 128, to nie zadziala...");

exit();

if yy>32:

print("Wysokosc wieksza od 32, to nie zadziala...");

exit();

if xx%2!=0 or yy%2!=0:

print("Szerokosc lub wysokosc nie jest potega 2, to moze nie zadzialac...");

data=i.load()

print("const unsigned char PROGMEM logo["+str(int(xx*(yy/8)))+"]= {") #rozpoczynamy tablice

for y in range(0,yy,8): #idziemy po wsp y obrazka

for x in range(0,xx): #idziemy po wsp x obrazka

b=0 #zerujemy wartosc bajt (wszystkie pixesle zgaszone)

for n in range(0,8): #sprawdzamy kolejne pionowe 8 pixeli na danej wsp. x

if y+n

The software and documentation of the microprocessor tester can be found here:

https://www.mikrocontroller.net/svnbrowser/transistortester/

I suspect that all available LCR testers have software based on these sources.

We click "Download GNU tarball" and extract the content (e.g. using 7zip).

We will use the source code to work with Atmel Studio 7.

After installing the Atmel Studio 7 environment, select:

File -> New -> GCC C Executable Project, select the ATMEGA328P microcontroller and create a project with the selected name in the selected location.

We copy all files from the directory with unpacked contents \ Software \ trunk \

to the directory of the created Atmel Studio project (where the .cproj file is),

then we agree to replace main.c.

Copy the "fonts" and "mega328_st7565" directories from the \ Software \ trunk \ directory to the project directory.

Right-click on the project name in the solution explorer window and select:

Add-> Existing items let's add all * .ci * .h files

Select project-> properties, select use external makefile and select the Makefile file from the "mega328_st7565" directory, in the project directory.

In the Makefile file we change:

UI_LANGUAGE = LANG_ENGLISH on UI_LANGUAGE = LANG_POLISH (if we want Polish menu)

CFLAGS + = -DLCD_ST7565_H_OFFSET = 4 per CFLAGS + = -DLCD_ST7565_H_OFFSET = 0 (image shift)

CFLAGS + = -DLCD_ST7565_V_FLIP = 1 per CFLAGS + = -DLCD_ST7565_V_FLIP = 0 (vertical flip)

CFLAGS + = -DLCD_ST7565_H_FLIP = 1 per CFLAGS + = -DLCD_ST7565_H_FLIP = 0 (level reversal)

I also experimentally turned on:

CFLAGS + = -DWITH_UJT (Option WITH_UJT enables additional tests for UJT (UniJunction Transistor))

It's worth experimenting with the Makefile by reading the descriptions and documentation in \ Dock \ tags \ english

To generate files to be placed in the microcontroller's memory, select:

We choose Build-> Build Solution.

We should receive a message:

========== Build All: 1 succeeded, 0 failed, 0 skipped ==========

After completing the compilation, go to the "mega328_st7565" directory in the project directory, there is the TransistorTester.hex file (flash memory content) and TransistorTester.eep (eeprom content). Place both files in the memory of the ATMEGA328P microcontroller using the selected ISP programmer. I used AVRISP MKII and software from AtmelStudio environment. To connect to the ISP connector in the tester, I used the connecting cables for the contact plate. The photo below shows the pinout of the connector.

For the time of programming, we lock the button that turns on the device (e.g. with a clothes peg) to ensure continuous power supply of the microcontroller.

If everything goes well, the tester will greet us with messages in Polish:

We put our own logo.

Perhaps logo placement is not some super ambitious and necessary task, but it is a good way to start playing with tester code. We have an area of 128x32 black and white pixels at our disposal (during the ongoing test). We'll write each pixel as a bit in a byte, and that takes 512B in a 512-element array. Each byte will be a vertical 8-pixel dash starting at the top of the x-coordinate of the LSB bit of the array element. After reading as many elements as the image width is (in our example 128), we read the next bar at the y-greek coordinate by 8 pixels.

If we care about the logo and limit the memory consumption, we can think about a simple "compression", for example saving the coefficient of start and end lines horizontally or vertically instead of data for all pixels, for some pictures it will save memory.

The black and white elektroda.pl logo from the home page is saved to a PNG file with a resolution of 128x32:

With a simple python code, we convert a PNG file into an array, in which each bit corresponds to a lit or unlit pixel on the LCD. We set the height and width of the PNG file so that they are equal to the power of 2. For a 128x32 image we will have 128x (32/8) = 512 element array, a single element of the array will be a byte. To write the codes, we use the knowledge gained about python and png here:

Will the Sun clear the EPROM?

Quickly written python 3 code will turn the PNG file into an array of bytes:

[syntax=python]from PIL import Image

i = Image.open("logo.png")

xx=i.width

yy=i.height

print("szerokosc: "+str(xx)+" wysokosc: "+str(yy))

if xx>128:

print("Szerokosc wieksza od 128, to nie zadziala...");

exit();

if yy>32:

print("Wysokosc wieksza od 32, to nie zadziala...");

exit();

if xx%2!=0 or yy%2!=0:

print("Szerokosc lub wysokosc nie jest potega 2, to moze nie zadzialac...");

data=i.load()

print("const unsigned char PROGMEM logo["+str(int(xx*(yy/8)))+"]= {") #rozpoczynamy tablice

for y in range(0,yy,8): #idziemy po wsp y obrazka

for x in range(0,xx): #idziemy po wsp x obrazka

b=0 #zerujemy wartosc bajt (wszystkie pixesle zgaszone)

for n in range(0,8): #sprawdzamy kolejne pionowe 8 pixeli na danej wsp. x

if y+n

Cool? Ranking DIY