The culprit is the oscilloscope.

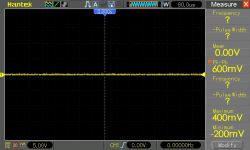

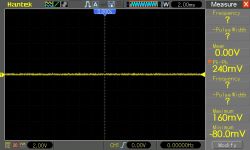

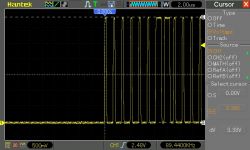

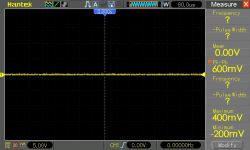

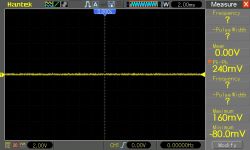

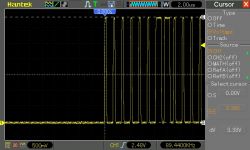

It seems that the measurements are made from what he "sees" on the screen. And since the base is quite thick (noise?), it is included in the measurement. The peak value is different for different voltage ranges per division. This is what it looks like for the 5V and 2V range per plot. Best when measuring with a cursor. To sum up, it`s probably a problem with budget equipment (DSO5102BM)...

It does not matter whether the probe is connected, shorted to ground or disconnected.

5V range:

2V range:

cursor measurement. 500mV range:

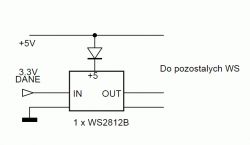

Returning to the topic of WS2812B. The waveforms (amplitude) on the GPIO controlling the WS are identical with and without the tape connected. So nothing works retroactively with WS here. At least 5V. So ESP is safe in my opinion.

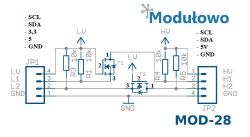

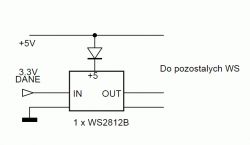

And I must admit that the system I propose works at the border of the WS specification. With a 3.3 -> 5V driver, the system will certainly be reliable. I found an interesting patent on the Internet using a single WS2812. There is not always a driver at hand.

The only thing is that the WS +1 addresses need to be renumbered in the software

It seems that the measurements are made from what he "sees" on the screen. And since the base is quite thick (noise?), it is included in the measurement. The peak value is different for different voltage ranges per division. This is what it looks like for the 5V and 2V range per plot. Best when measuring with a cursor. To sum up, it`s probably a problem with budget equipment (DSO5102BM)...

It does not matter whether the probe is connected, shorted to ground or disconnected.

5V range:

2V range:

cursor measurement. 500mV range:

Returning to the topic of WS2812B. The waveforms (amplitude) on the GPIO controlling the WS are identical with and without the tape connected. So nothing works retroactively with WS here. At least 5V. So ESP is safe in my opinion.

And I must admit that the system I propose works at the border of the WS specification. With a 3.3 -> 5V driver, the system will certainly be reliable. I found an interesting patent on the Internet using a single WS2812. There is not always a driver at hand.

The only thing is that the WS +1 addresses need to be renumbered in the software