Hello

Watches featuring WS2812B have already been published on Elektroda. I would like to present my version. I had some of this tape left over from recent projects and decided to use it. Access to a 3D printer may make this project difficult.

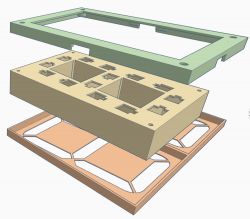

The clock has digits that are 79 mm high. It`s big, but you get used to it. After several experiments, it seems that this height is optimal when using the most popular strip with a density of 60 LED/m. In addition to the dots, there are two diodes (on the tape) per digit segment. I also tested with smaller displays. The minimum height is 45mm (one diode per segment, without removing the LED from the strip).

The clock shows the days of the week in addition to the time. A friend of mine talked me into it and I think it was a good idea. The day display can be placed above or below the numbers. The current time is downloaded from NTP servers every hour by default. Undoubtedly, the advantage of this design is the almost unlimited display in terms of colors and animations. You can also link the display to the calendar and display different patterns on specific dates.

All elements except the back wall (HDF) are printed from PLA. The mounting frame is glued from two parts.

And as a finishing touch, a furniture edge is pressed onto it.

I glued the partition-type elements from the inside with white self-adhesive foil. In my opinion it goes faster than painting white. And the job is clean.

After unsuccessfully searching for white PVC for matte screens, I experimented with a white print. I think it looks quite nice. Up close you can barely see the print threads, but from a distance of several dozen centimeters you have to look closely to see them. And if someone doesn`t know about their existence, they don`t notice them :)

connected sections of tape

installation

More interesting patterns

I called this pattern "Patriot". Good for days off from work

Very slow vertical color change.

The remaining patterns are different display colors. There are 9 of them.

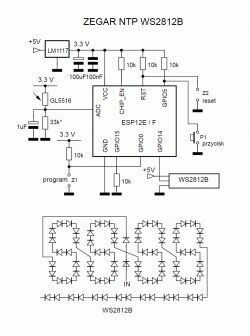

Electronics:

I still have to think about the GUI. I am attaching the development code in the Arduino IDE.

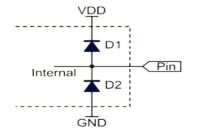

device diagram

Well, that`s it in a nutshell