Hi,

This is my first post in the forum, so apologize if something is out of the rules.

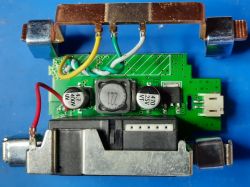

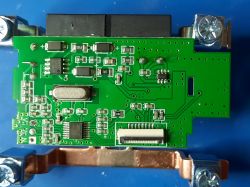

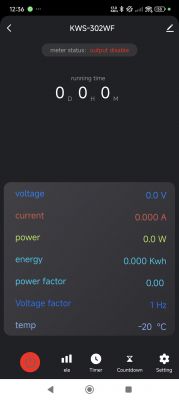

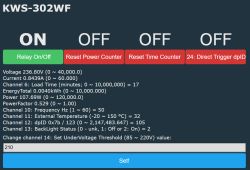

Recently I bought one Power Meter KWS-302WF and didn't like the way it used to current measuring. So I dismantled the device to see if I'm able to change from shunt to transformer.

This is the beginning of the story.

I saw the measuring chip is an HT7017 from HitrendTech, which is handled by a PY32F002A, by it turn gives the commands to a TM1622 which handles the display.

The WiFi chip is a CBU (BK7231N ?) connected to PY32F.

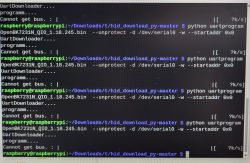

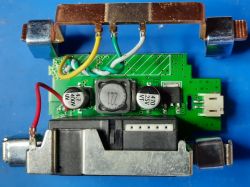

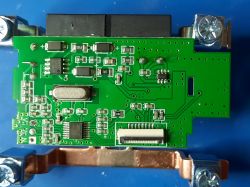

I made some soldering work and intercepted the communications between the CBU and the PY32F (and also between this one and the HT7017).

Following there are some photos and some files with the comm data.

Let see if this will be useful to change the firmware in the CBU ...

This is my first post in the forum, so apologize if something is out of the rules.

Recently I bought one Power Meter KWS-302WF and didn't like the way it used to current measuring. So I dismantled the device to see if I'm able to change from shunt to transformer.

This is the beginning of the story.

I saw the measuring chip is an HT7017 from HitrendTech, which is handled by a PY32F002A, by it turn gives the commands to a TM1622 which handles the display.

The WiFi chip is a CBU (BK7231N ?) connected to PY32F.

I made some soldering work and intercepted the communications between the CBU and the PY32F (and also between this one and the HT7017).

Following there are some photos and some files with the comm data.

Let see if this will be useful to change the firmware in the CBU ...