Update, it's been over a month since the magazine completely paid for itself, so after a full financial 'blip', everything is now going to the upside.

As befits an experimental magazine - the experiment continues - and the mothballing continues

Next news, sometime in March I noticed that some of the cell sockets from one batch started to crack after a while, so within two weeks (fortunately these were weeks of no sunshine at all) the storage unit was rebuilt to mechanically prevent this kind of malfunction in the future. The cracked sockets were replaced. The sockets that have the print on them are OK and nothing happens to them, but the ones from the Chinese supplier that don't have such prints and numbers - they started to break, so

I LOSE to the quality of some Chinese stuff.

Below are pics of how they break down and how I rebuilt the magazine (disassembling/disassembling it was one afternoon - I was surprised myself how quickly you can take something apart

) . This info would actually need to be added to the first post.

.

.

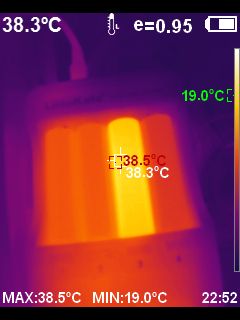

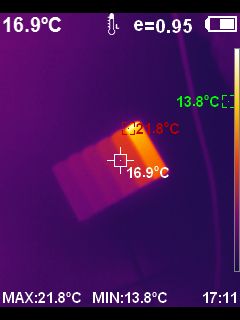

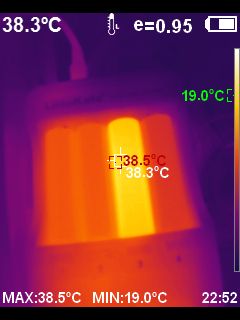

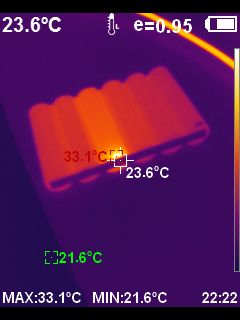

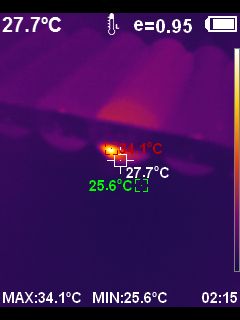

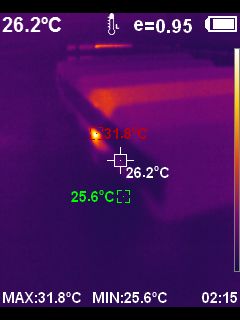

By the way, I throw in an example of a cell caught during a periodic thermal imaging inspection, a point of higher temperature by 3 degrees relative to the background, a cell that got a slight leak (after removing the tee shirt, I found a tiny electrolyte leak, a droplet). There was still a long way to go before such a cell was destroyed, maybe 3-6 months, but the thermal imaging had already caught the "dude" early enough - the cell was of course replaced immediately (without shutting down the storage), service-wise the design works.

Here the thought really comes to mind that if the factory packs were not sealed and people/users were able to check with thermal imaging, the number of different "accidents" could be significantly reduced.

partyzancik wrote:

@remzibi and if the cells heat up when charging do you just blow it off? I have had sanyo cells heat up even when charging with tp4056 and I have thrown all the batteries with them in the scrap

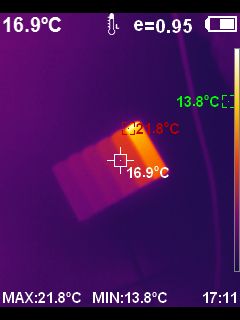

Yes, with a 700mA landing current, anything above 40 deg C drops out automatically, cells usually start to heat up when charged above 3.9V, charging of course I check with thermal imaging and not "finger"

.

Example photo of a thermo cell which will be discarded in a moment