rudzik1 wrote: Execution and monitoring 1st class - respect. Would you be able to add some current photos of the magazine? When filling it was it first lying horizontally and then you raised it (I infer from the photos)? What wire did you use to connect the baskets (as a rail of individual strings)? Where did you get the baskets from that give advice (e.g. the name of the retailer on the platform in question)?

Well, and how has the magazine performed recently?

Thanks for the good word

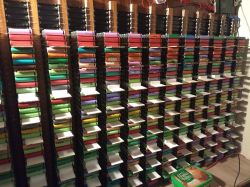

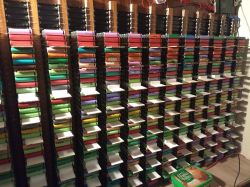

Current photo.

The storage unit was designed from the start to be standing, for the destination it was to be placed in, but still has castors at the bottom for easy movement if needed.

In the photo you can also see the spacers every 4 links (the gap between the cages), and the two rows of printed wedges (the white ones),

which compensate for the slight drooping of the links on the higher floors (the diameters of the different links are not identical).

Connecting the baskets using 2.5mm square copper wire soldered to the basket terminals. And between the "backs" of the terminals and the terminals, sections of 0.1mm wide 5mm weld metal plates are inserted/inserted, in order to better treat the 4 terminals in one basket in case one of them has a worse solder with this 2.5mm square rail wire.

The 4A fuses are soldered directly to the terminal blocks and on the other side to the rail.

Baskets from Ali, I recommend the better ones with embossed lettering, the plain ones unfortunately cracked, but building a base with gutters for the baskets generally solves the cracking problem - as it prevents cracking.

So far the storage is working great, now in November when there is no sunshine, the table is mostly milked, but if the sunshine shows up - then of course it charges up as much as it can, and lasts for the next hours/days.