Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tam

bumble wrote:..

And why. You hang such a thing on the wall and use it, when the heater dies you replace the heater or the whole thing. An electrode is probably once every 15 years. I've never heard of such devices being serviced. Unless you boil water in it, that's different.

.

.

{

"VER": "01",

"R1": "0054",

"R2": "00B4",

"R3": "00C4",

"R4": "0264",

"R5": "0274",

"R6": "0304",

"ED": "03F4",

"HFG": "000342422102",

"HHW": "460130051002_93D2500900",

"HHW_raw": "460130051002_93D2500900",

"HSW": "660060273204_25.04.00",

"HSN": "SERIAL_OMITTED",

"TST": "PNNPNNN",

"ECN": "93D2303400",

"VER2": "01",

"LD1": "NO",

"LD2": "NO",

"LD3": "00",

"MKT": "EU",

"TP1": "000",

"TP2": "000",

"TP3": "000",

"WIF": "1",

"INI": "0",

"TMN": 40,

"TMX": 80,

"TSP": "01",

"TDF": 70,

"THY": 5,

"ABT": 60,

"ABD": 60,

"ABF": 30,

"ABS": 1,

"ALT": 60,

"ALS": 0,

"AFT": 16,

"AFH": 11,

"ECT": 40,

"ECS": 1,

"QIK": 0,

"AIO": "00",

"AIS": "00",

"AOO": "00",

"AOS": "00",

"SRT": 40,

"SRS": 1,

"HEF": 2,

"LT1": 40,

"LT2": 50,

"LT3": 60,

"LT4": 70,

"LT5": 80,

"LO1": 30,

"LO2": 38,

"LO3": 48,

"LO4": 60,

"LO5": 70,

"DLY": 540,

"BUZ": 1,

"POS": "M",

"CAI": 32,

"CAO": 32,

"DIA": 220,

"PI1": 1500,

"PI2": 0,

"PO1": 1500,

"PO2": 0,

"CK3": "555A",

"TFG": "XXXXXXXXXXXX",

"NIN": "XXXXXXXXXXXX",

"NOU": "XXXXXXXXXXXX",

"BFG": "3100946",

"PLT": 5,

"YDY": 25169,

"BSN": 4430416,

"NFC": "X",

"SAT": "XXXXXXXXXXXX",

"R1C": "000008",

"R2C": "000038",

"R3C": "000000",

"H1H": "000000",

"H2H": "000002",

"H3H": "000000",

"PSO": "000007",

"PSK": "000001",

"POH": "000024",

"ER1": "XXX",

"ER2": "XXX",

"ER3": "XXX",

"ER4": "XXX",

"ER5": "XXX",

"LMD": "MAN",

"LTS": 70,

"LAB": 1,

"MAC": "MAC_OMITTED",

"WSN": "SERIAL_OMITTED"

}

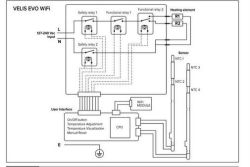

C3 41 -> frame header

33 -> WiFi CMD designator

04 -> data length

79 2D -> set/change temperature command

b2 02 -> u16 based LE temp/10 -> 2b2/10=69.0

95 -> checksum