thanks a lot for your reply!

Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tam

farmazon3000 wrote:marcingeneral how wide are your belt drive pulleys? I was thinking about replacing them with pulleys from the washing machine, which are ridiculously cheap compared to yours

marcingeneral wrote:

The diameter of my wheels is 58cm. The wheels from the washing machine are about 30 cm.

marcingeneral wrote:

If you want to significantly reduce construction costs, use, for example, hubs from the rear axle of Golf 1 (full on each road) and temporary wheels on solid rubbers.

The turner will roll you such access roads and you can balance them on vulcanization.

And to work. I am curious about the effects.

andrzej2504 wrote:Hello, I wanted to know how much wood is roughly sawn on one saw 1.1 / 35/4005

andrzej2504 wrote:

I meant how many m2 saws break.

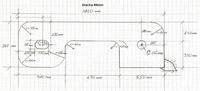

andrzej macioł wrote:Hello, for a few months I have been collecting materials for such a sawmill I already have wheel profiles, tape and motors, I still miss the end switches because I can see that you have a request if you could chew more photos of the slope and on the other hand, because it seems to me that there is a clock next to the left wheel what is it when I start my sawmill and send it based on your acha what is your engine power I have to carry 0.8kw 800 revs belt tension 4kw1400 revolutions for 2kw feed 800 revolutions