It depends on what you mean by 'smoothing'. I simply sand on sandpaper. Silicone to restore the colour after sanding (it can evaporate after a long time). There can also be a thin layer of matt clear varnish. It depends on what effect you want to achieve. PLA is quite hard to work with. A lot also depends on the shape of the solid.

Instead of "stroking" a solid, you can also use different veneers for simple solids. Be careful with iron-on veneers, as the melting point of the glue is similar to that of PLA. But it is possible . Complex solids are certainly more difficult to process. Sometimes I prefer to print something from smaller pieces and after machining them together. I print on glass, so one wall is like a mirror. Worse with vertical ones.

. Complex solids are certainly more difficult to process. Sometimes I prefer to print something from smaller pieces and after machining them together. I print on glass, so one wall is like a mirror. Worse with vertical ones.

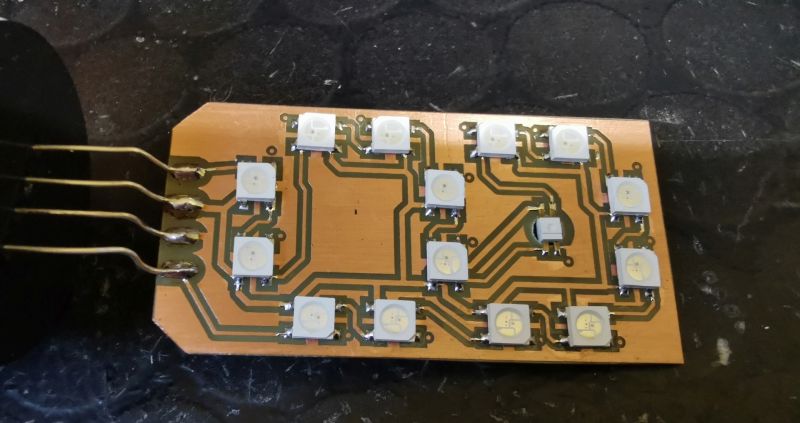

Examples of veneer: here it is thicker on filament (0.6mm), but there are also thin furniture veneers with glue in sheets.

Instead of "stroking" a solid, you can also use different veneers for simple solids. Be careful with iron-on veneers, as the melting point of the glue is similar to that of PLA. But it is possible

Examples of veneer: here it is thicker on filament (0.6mm), but there are also thin furniture veneers with glue in sheets.