Krzychu1843 wrote: If any of you have this amplifier on the table, I would have a small request. I need to know the value of the capacitor at sg3525a marked C196. My meter shows 390pF and this is inconsistent with what you can read in the catalog note of the system

And here we come to the merits of the case. Probably the manufacturer used a version of the system dedicated to him, because the system has been produced in a dozen or so companies over the years and as a property it was also sold to competitors on the production market several times. In addition, there are licensed products with the same or similar designation. Despite this, the old catalog notes from the time of paper catalogs from the 1980s and 1990s are still widely available today. In addition, the system was produced in various versions, including military and professional industrial ones. It is a fact that the available catalog note in many production executions does not fully reflect the applied R, C values of the generator, and dead time, and yet such systems work properly and sometimes for decades.

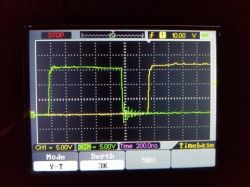

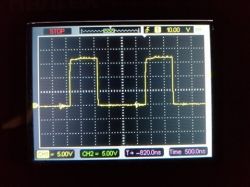

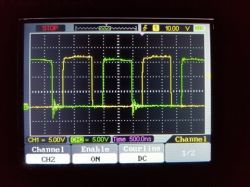

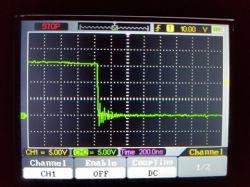

It remains to check the practical frequency of work, the dead time for the entire implementation system and the selection of elements.

In our serviced amplifiers, the value of the Ct capacitor (up to pin 5) was different for individual units from different production periods. Usually these values were: 330,390,420,430pF (measured with a laboratory bridge at a measuring frequency from 1kHz to 1MHz). Similarly with the 470-620 ohm dead time resistor.

rzepong wrote: In one driver the bootstrap has 3.3 uF, in the other 2.6 uF. Could the reduced capacity of the bootstrap cause incomplete opening of the transistor and large heat losses on it, which causes it to burn quickly?

Basic knowledge, what is the purpose of bootstrapping and how does it work? What might a capacity deviation indicate?

A good rule of thumb in the event of damage to such elements as IGBT drivers is to replace all elements that work directly with the damaged system. Prophylactically.

Krzychu1843 wrote: In total, if we collect the values of individual elements, we could think about creating a spreadsheet file that would facilitate further repairs.

The only thing is that those who can fix it right away have been on the market for years, and the product is already slightly old and has a shameful history among users. Hardly any serious acoustician, sound director or even a DJ decides to repair this amplifier, let's add a costly repair. If someone tries to repair this equipment based on commonly available components in the retail trade for a total amount of less than 1/2 of the market value of this amplifier, he is hoeed to the sun and is incorrect optimists. For this reason, we gave up in my company. But I don't want to confuse you, it's all ahead of you, colleagues.