still only those IDs

Code: JSON

Czy wolisz polską wersję strony elektroda?

Nie, dziękuję Przekieruj mnie tam

V:BK7231N_1.0.1

REG:cpsr spsr r13 r14

SVC:000000D3 00401C1C 000033AC

IRQ:000000d2 00000010 00401e0c eee356f7

FIR:000000d1 00000010 00401ffc f9c5abad

SYS:000000df 0040192c 00000158

ST:00000000

J 0x10000

bk_misc_init_start_type 0 0

prvHeapInit-start addr:0x4144f0, size:113424

[Flash]id:0xeb6015

sctrl_sta_ps_init

cset:0 0 0 0

OpenBK7231N, version 1.18.176

Entering initLog()...

Commands registered!

initLog() done!

Info:MAIN:Main_Init_Before_Delay

undefined instruction

Current regs:

r00:0xdd3000e2

r01:0x00000000

r02:0x005dd352

r03:0x00000052

r04:0x005dd300

r05:0xffbf767f

r06:0x003ff1ce

r07:0xdd300000

r08:0x08080808

r09:0x09090909

r10:0x10101010

fp :0x11111111

ip :0xffe38350

sp :0x00406070

lr :0x0080006e

pc :0x0080006e

SPSR:0x800000ff

CPSR:0x800000db

separate regs:

SYS:cpsr r8-r14

0x800000df

0x08080808

0x09090909

0x10101010

0x11111111

0xffe38350

0x00415618

0x003ff1b7

IRQ:cpsr spsr r8-r14

0x800000d2

0x6000001f

0x08080808

0x09090909

0x10101010

0x11111111

0xffe38350

0x004078a8

0x003ffd70

FIR:cpsr spsr r8-r14

0x800000d1

0x00000010

0x00000000

0x00000000

0x00000000

0x00000000

0x00000000

0x004068b8

0xf9c5abad

ABT:cpsr spsr r8-r14

0x800000d7

0x00000010

0x08080808

0x09090909

0x10101010

0x11111111

0xffe38350

0x004060b8

0x9980fef0

UND:cpsr spsr r8-r14

0x800000db

0x800000ff

0x08080808

0x09090909

0x10101010

0x11111111

0xffe38350

0x00406068

0x0080006e

SVC:cpsr spsr r8-r14

0x800000d3

0x200000df

0x08080808

0x09090909

0x10101010

0x11111111

0xffe38350

0x00408078

0x0008b360

shutdown...fjcns wrote:In my case, it wasn't necessary to desolder the MCU pins.

.....

[Flash]id:0xeb6015

sctrl_sta_ps_init

cset:0 0 0 0

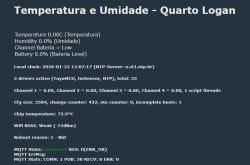

OpenBK7231N, version 1.18.206

Entering initLog()...

Commands registered!

initLog() done!

Info:MAIN:Main_Init_Before_Delay

<hangs here>

#define DISABLE_FLASH_VARS_VARSclearIO

PowerSave 1

startDriver NTP

// ntp_setServer pool.ntp.org

ntp_setServer 192.168.40.1

// EEST time zone

alias winter_time ntp_timeZoneOfs 2

alias summer_time ntp_timeZoneOfs 3

winter_time

// summertime

alias check1 if $month>3 then summer_time

alias check2 if $month==3&&31-$mday+$day<=6&&$day>0 then summer_time

alias check3 if $month==3&&31-$mday+$day<=6&&$day=0&&$hour>=2 then summer_time

// wintertime

alias check4 if $month>10 then winter_time

alias check5 if $month==10&&31-$mday+$day<=6&&$day>0 then winter_time

alias check6 if $month==10&&31-$mday+$day<=6&&$day=0&&$hour>=3 then winter_time

alias set_time backlog check1;check2;check3;check4;check5;check6

startDriver TuyaMCU

startDriver tmSensor

setChannelType 1 temperature_div10

linkTuyaMCUOutputToChannel 1 val 1

setChannelType 2 Humidity

linkTuyaMCUOutputToChannel 2 val 2

setChannelType 3 ReadOnlyLowMidHigh

setChannelLabel 3 "Batt_state"

linkTuyaMCUOutputToChannel 3 val 3

waitfor NTPState 1

set_timeclearIO

PowerSave 1

startDriver NTP

ntp_setServer 192.168.1.1

// EDT-EST time zone

alias winter_time ntp_timeZoneOfs -5

alias summer_time ntp_timeZoneOfs -4

winter_time

// summertime

alias check1 if $month>3 then summer_time

alias check2 if $month==3&&31-$mday+$day<=6&&$day>0 then summer_time

alias check3 if $month==3&&31-$mday+$day<=6&&$day=0&&$hour>=2 then summer_time

// wintertime

alias check4 if $month>10 then winter_time

alias check5 if $month==10&&31-$mday+$day<=6&&$day>0 then winter_time

alias check6 if $month==10&&31-$mday+$day<=6&&$day=0&&$hour>=3 then winter_time

alias set_time backlog check1;check2;check3;check4;check5;check6

startDriver TuyaMCU

delay_s 2

uartSendHex 55AA001000070101090400010026

startDriver tmSensor

setChannelType 1 temperature_div10

linkTuyaMCUOutputToChannel 1 val 1

setChannelType 2 Humidity

linkTuyaMCUOutputToChannel 2 val 2

setChannelType 3 ReadOnlyLowMidHigh

setChannelLabel 3 "Batt_state"

linkTuyaMCUOutputToChannel 3 val 3

waitfor NTPState 1

set_time

// now wait for MQTT

waitFor MQTTState 1

// now wait for channel 1 to become non zero

// if channel 1 is still 0, loop, wait 0.1s and check again

again:

delay_s 0.1

if $CH1==0 then goto again

publish DATA {"ROOM":"1","TEMPERATURE":$CH1,"HUMIDITY":$CH2}Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 40 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 40 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Info:TuyaMCU:Consumed 20 unwanted non-header byte in Tuya MCU buffer

Info:TuyaMCU:Skipped data (part) 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

if $CH1==0 then goto again

uartSendHex 55AA001000070101090400010026flecom wrote:I've got one of these with a BK7238, flashed it with openbk and made an autoexec that looks like this:

{

"1": "Temperature",

"2": "Humidity",

"3": "Battery Status",

"9": "Temperature Unit",

"23": "Temperature Calibration",

"24": "Humidity Calibration"

}

{

"modelId": "e1n3p63s",

"dpids": {

"1": {

"code": "temp_current",

"name": "Temperature",

"access": "read_only",

"type": "value",

"unit": "°C",

"scale": 1,

"min": -99,

"max": 600

},

"2": {

"code": "humidity_value",

"name": "Humidity",

"access": "read_only",

"type": "value",

"unit": "%",

"scale": 0,

"min": 0,

"max": 100

},

"3": {

"code": "battery_state",

"name": "Battery Status",

"access": "read_only",

"type": "enum",

"values": [

"low",

"middle",

"high"

]

},

"9": {

"code": "temp_unit_convert",

"name": "Temperature Unit",

"access": "read_write",

"type": "enum",

"values": [

"c",

"f"

]

},

"23": {

"code": "temp_calibration",

"name": "Temperature Calibration",

"access": "read_write",

"type": "value",

"unit": "°C",

"scale": 1,

"min": -20,

"max": 20

},

"24": {

"code": "hum_calibration",

"name": "Humidity Calibration",

"access": "read_write",

"type": "value",

"unit": "%",

"scale": 0,

"min": -10,

"max": 10

}

}

}