NiceMCU_WB3S_V1 is a very cheap (possible to buy for as low as 1-2$) Beken development board. It comes with BK7238 chip, but with some soldering it's also possible to very easily swap the BK7238 module with any classic Tuya WB2S or CB2S and still get correct GPIO markings. Here I will show you how I've done it.

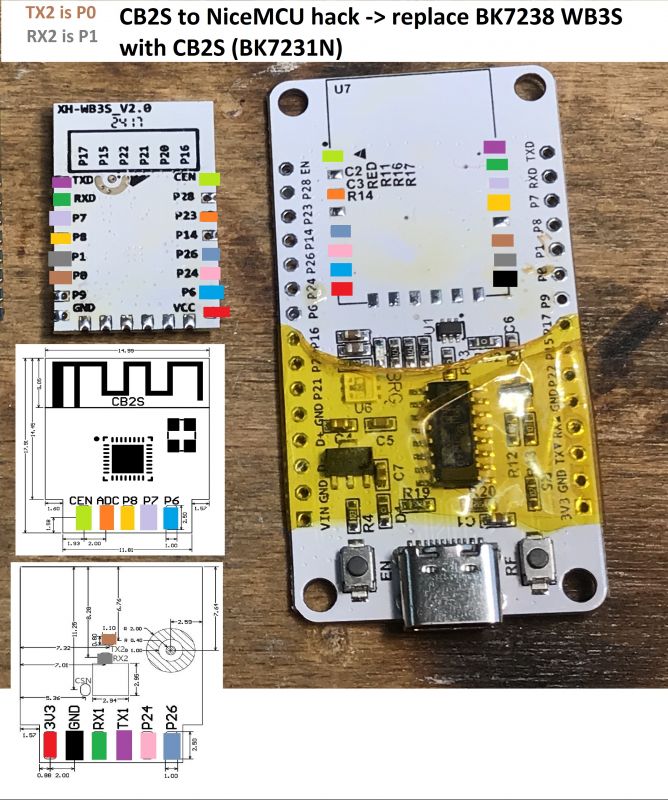

The basic idea is to just get WB2S/CB2S, get some Ethernet wires and just solder the pads to their correct places, so the GPIO names on the board are correct.

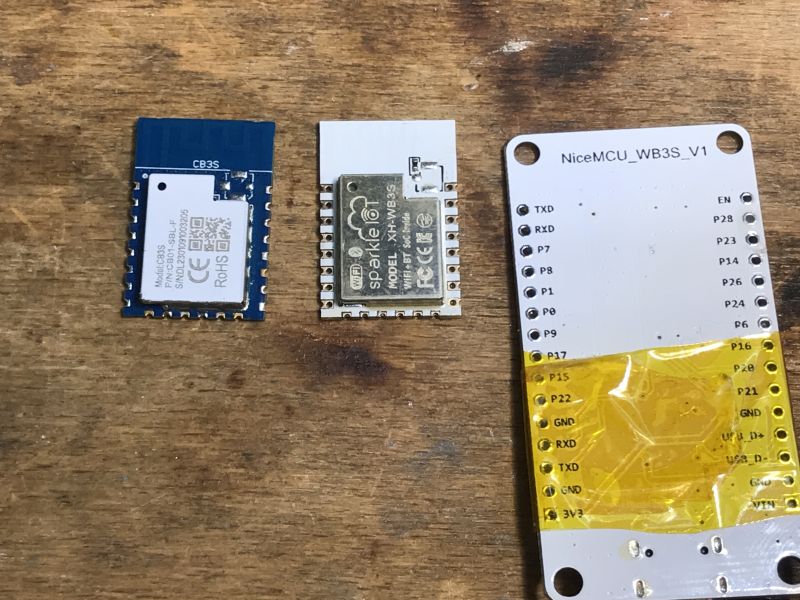

So first, you obviously need NiceMCU_WB3S_V1 board, which has been already discussed here:

NiceMCU XH-WB3S BK7238 Flashing, Testing, Pinout, Development, Porting

You can get it for as low as about 1$ when you create new account:

Then you need to do a hot air BK7238 module removal, just like in my previous dev board hack (NodeMCU):

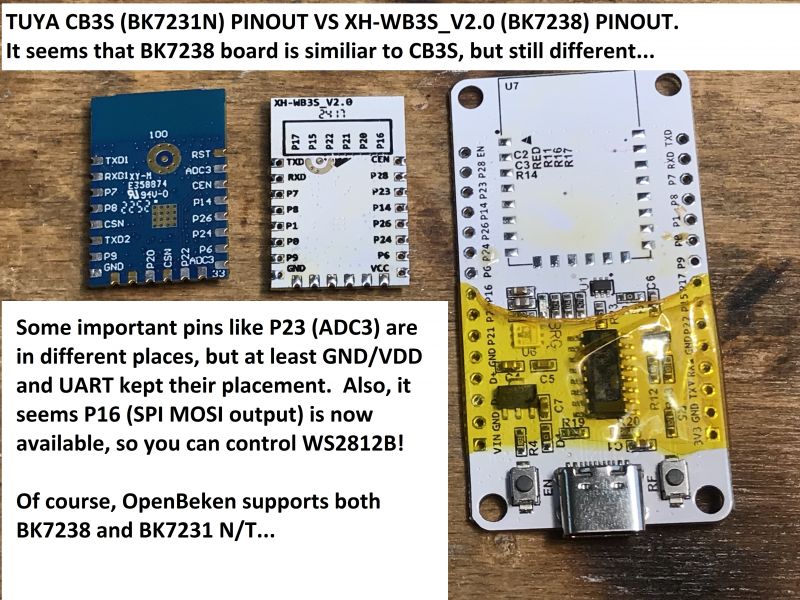

By the way, here is pinout of BK7238 module:

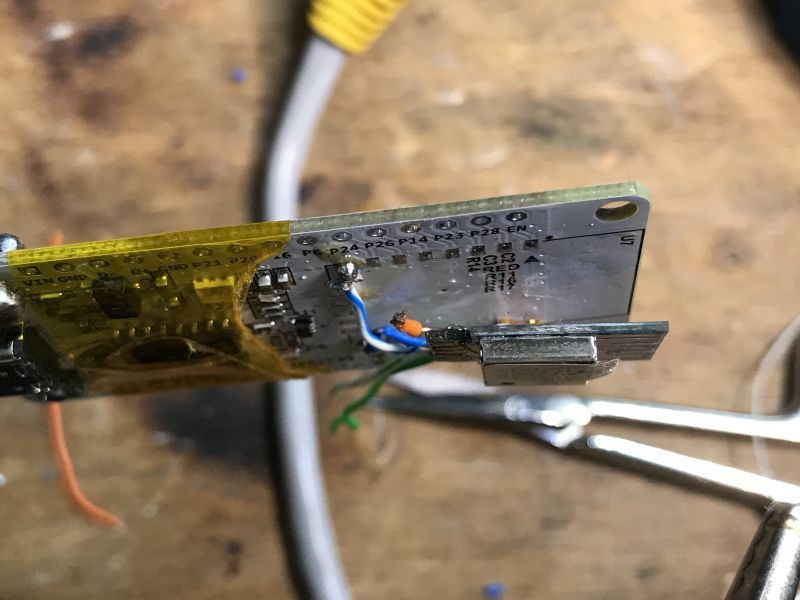

Here is the other side view:

Ok, with this information, we can just mark which pin goes where:

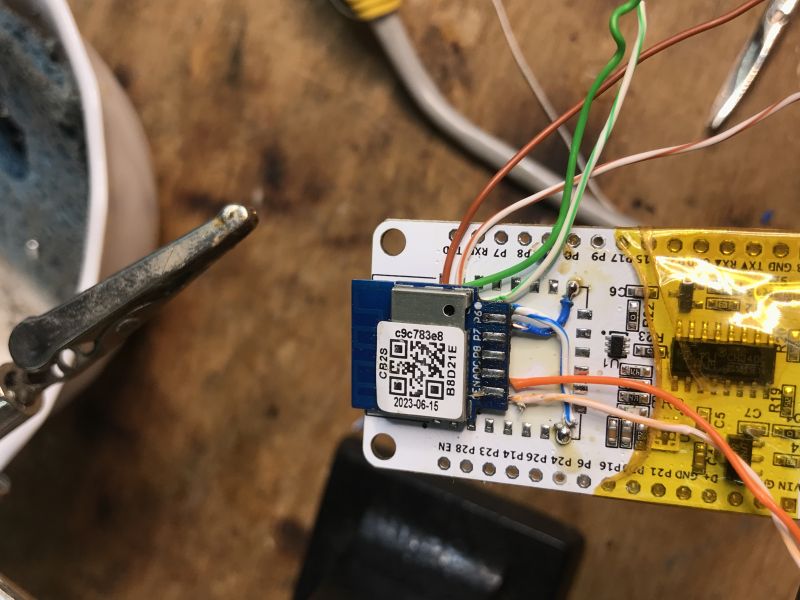

In this particular case, I've used BK7231M (not N) CB2S, but it does not matter, pins are the same.

I'm using such wires:

Soldering should be very easy. Just follow the simple guidelines:

- always keep soldering iron tip clean

- use flux and Pb soldering iron (as it has lower melting point)

- first apply solder separately to wire and to the pad, then solder wire to the pad

- make sure to strip insulation from wires first

- avoid bending wires repeatedly or they may snap

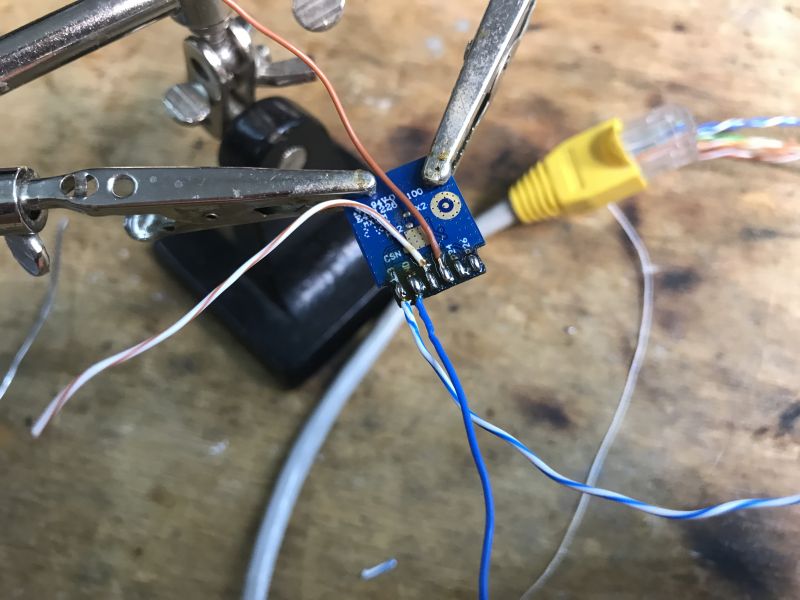

While soldering wires, make sure to check where they should go and chose the best wire orientation:

Placement time:

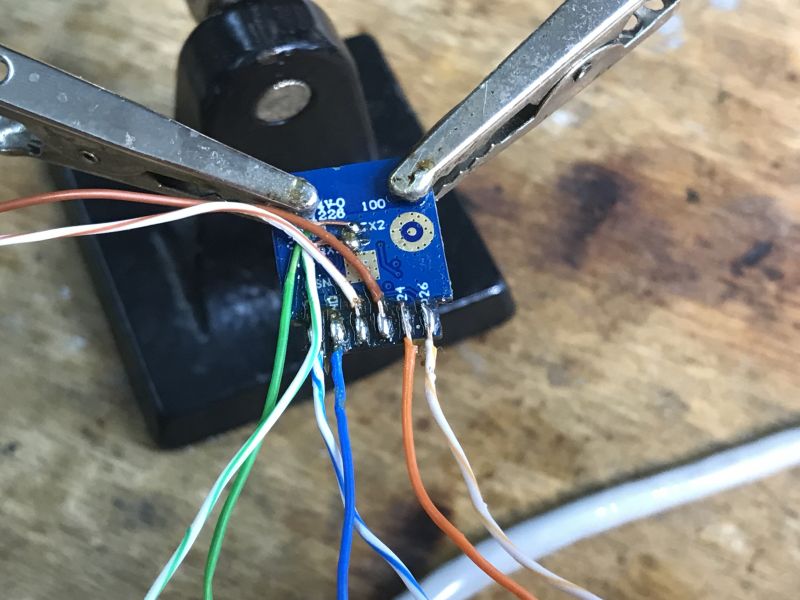

Some little corrections:

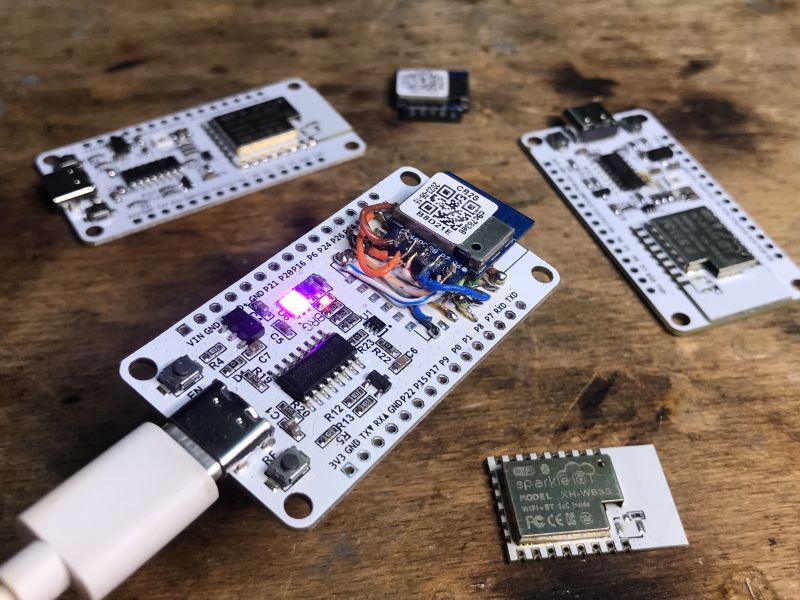

Initial test with our flasher:

Almost ready:

Complete product:

Now all of CB2S pins (even RX2 and TX2, which are on module back) are routed to their correct places on the board. Futhermore, the onboard LED also works (PWM0 and PWM4 pins seems to control it).

This way our new CB2S dev board is complete and it's better than NodeMCU hack because the markings on the board (like P9, P1, etc, TX, etc) are correct, so it's easier to quickly assembler a test setup with it. Now it's ready to be used for some OpenBeken development and testing.

PS: There is also our CB2S/WB2S to CB3S/WB3S converter available, which we've shown here, but it does not route RX2/TX2 and the module is perpendicular to mother board, which increases it's height greatly...

Cool? Ranking DIY Helpful post? Buy me a coffee.